Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

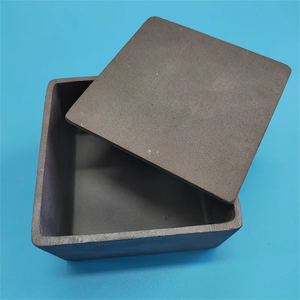

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Factory supply Refractory Crucible High Pure Silicon Carbide Graphite Crucible)

Specification of Factory supply Refractory Crucible High Pure Silicon Carbide Graphite Crucible

This product is a high-performance refractory crucible made for commercial applications. It combines silicon carbide and graphite to develop a durable, heat-resistant container. The major material is high-purity silicon carbide, making sure security under extreme temperatures. Graphite is contributed to boost thermal conductivity and resistance to splitting. The crucible deals with temperatures up to 1600 ° C, making it suitable for thawing metals, alloys, and various other products. Its thermal shock resistance stops damages during rapid home heating or cooling cycles. This function decreases downtime and prolongs service life popular environments.

The crucible has a dense framework with reduced porosity, reducing material penetration during melts. This design preserves purity in processes needing contamination-free outcomes. Its chemical inertness stands up to reactions with acidic or alkaline substances, keeping integrity across various applications. The smooth inner surface enables very easy removal of solidified materials, reducing waste and cleansing initiative.

Offered in several sizes, the crucible sustains small-scale lab usage and large commercial operations. Requirement dimensions range from 50mm to 500mm in diameter, with custom options for specialized requirements. The light-weight layout contrasted to typical clay crucibles boosts dealing with effectiveness. It deals with induction heaters, resistance heaters, and gas-fired arrangements, offering convenience throughout home heating approaches.

Manufacturing complies with stringent quality control to guarantee consistency in material make-up and efficiency. Each crucible undergoes testing for thermal stability, tons capability, and leak resistance prior to shipment. The item is packaged securely to stop transportation damages, with foam inserts and enhanced cardboard boxes.

Users in metallurgy, jewelry making, and research study labs gain from its dependability. It melts gold, silver, light weight aluminum, copper, and other non-ferrous metals efficiently. The crucible’s high wear resistance lowers substitute regularity, decreasing long-term expenses. Maintenance involves basic cleaning with non-abrasive devices to protect the surface area. Storage recommendations include maintaining it dry to stay clear of moisture absorption, which could influence efficiency.

This crucible satisfies international requirements for refractory products, guaranteeing compatibility with global commercial requirements. It is a functional option for high-temperature procedures requiring accuracy and sturdiness.

(Factory supply Refractory Crucible High Pure Silicon Carbide Graphite Crucible)

Applications of Factory supply Refractory Crucible High Pure Silicon Carbide Graphite Crucible

Factory supply refractory crucibles made from high-purity silicon carbide graphite serve critical functions in markets requiring severe heat resistance and toughness. These crucibles handle temperatures going beyond 1600 ° C, making them perfect for thawing steels like gold, silver, copper, and alloys. Their high thermal conductivity ensures quick warmth circulation, reducing power consumption throughout prolonged procedures. Thermal shock resistance allows abrupt temperature modifications without fracturing, an usual issue in metal casting or glassmaking processes.

In metal foundries, these crucibles stand up to repeated heating and cooling down cycles, maintaining architectural honesty in time. Their non-reactive surface area prevents contamination of liquified steels, guaranteeing purity in final products. Glass manufacturing relies on them to melt resources at heats, as their chemical stability stays clear of undesirable reactions with silica or ingredients. This assures clear, defect-free glass outputs.

Chemical handling plants make use of these crucibles for handling corrosive materials or high-temperature chemical reactions. Silicon carbide graphite stands up to acids, alkalis, and molten salts, making it appropriate for synthesizing sophisticated porcelains or refining rare planet components. Laboratories use them in material research study, where precise temperature control and contamination-free settings are necessary.

The electronics market take advantage of their capability to produce high-purity silicon crystals for semiconductors. Their toughness supports continuous usage in crystal growth heating systems, reducing downtime for substitutes. Fashion jewelry manufacturers value them for crafting detailed layouts without impurities impacting rare-earth elements.

High-purity silicon carbide graphite crucibles outlive traditional clay or ceramic options, decreasing long-term expenses. Their lightweight design reduces handling compared to bulkier choices. Adjustable sizes and shapes deal with details industrial requirements, from small workshops to large assembly line. Very little upkeep requirements and compatibility with induction heating systems additionally enhance their functionality.

These crucibles are indispensable in setups demanding dependability under tension. Efficiency stays regular across differing oxygen degrees or hostile chemical direct exposures. Individuals report fewer issues in final product and enhanced functional effectiveness because of reduced crucible failing rates.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory supply Refractory Crucible High Pure Silicon Carbide Graphite Crucible

What is a refractory crucible made from?

The refractory crucible combines high-purity silicon carbide and graphite. These materials handle extreme heat and resist chemical reactions. The mix ensures durability in harsh environments. This crucible works well for melting metals and alloys.

What temperature can this crucible withstand?

It handles temperatures between 1600°C and 1800°C. The silicon carbide boosts heat resistance. Graphite adds stability under rapid temperature shifts. This makes it reliable for repeated high-heat tasks.

What industries use these crucibles?

They suit foundries, jewelry making, labs, and metal recycling. The crucible melts gold, silver, aluminum, and copper. It works in furnaces or induction heating systems. Its toughness fits both small workshops and large factories.

How does it compare to clay or ceramic crucibles?

It lasts longer than clay or ceramic options. Silicon carbide resists cracks from thermal stress. Graphite improves heat transfer. These features reduce energy use. Maintenance costs stay low over time.

How do I maintain this crucible?

Clean it after each use to remove residue. Check for cracks or wear before reheating. Store it in a dry place to avoid moisture damage. Proper care extends its lifespan. Avoid sudden cooling after heating.

(Factory supply Refractory Crucible High Pure Silicon Carbide Graphite Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Good Quality Factory 50kg 250kg Sic Silicon Carbide Sagger Graphite Crucible for Melting

China Polished Surface Smelting Pure Tungsten Crucible for

High Temperature Isostatic Graphite Crucible Pure Refractory Clay Gold Silicon Carbide Casting High Quality Melting Crucible

High Temperature Resistance Sic Silicon Carbide Ceramic Heating Crucible for Dry Herb Vaporizer

Graphite crucible With 27cm Diameter And 30 Cm Heigh Graphite-crucibl