Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

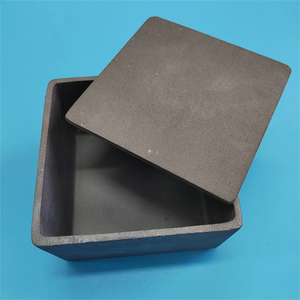

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(silicon carbide clay ceramic graphite melting pot crucible 30kg 40kg 100kg 200kg 500kg for induction furnace melting metal)

Specification of silicon carbide clay ceramic graphite melting pot crucible 30kg 40kg 100kg 200kg 500kg for induction furnace melting metal

This silicon carbide clay ceramic graphite fusion crucible handles tough steel melting work. It is available in a number of sizes: 30kg, 40kg, 100kg, 200kg, and 500kg capacities. These crucibles function flawlessly within induction heaters.

The material mix is key. Silicon carbide clay ceramic graphite produces a strong structure. This mix gives superb heat resistance. Crucibles encounter extreme heat inside heaters. These pots endure that warm well.

Thermal shock resistance is an additional significant benefit. Induction heaters heat up really quickly. Crucibles experience unexpected temperature changes. This material deals with fast heating and cooling cycles. It stands up to cracking and spalling. This durability indicates longer crucible life.

Chemical stability is critical also. Molten metals and slags are aggressive. The crucible product withstands chemical strike. This stops contamination of your thaw. It also lowers disintegration. Your steel stays cleaner. The crucible lasts much longer.

These pots help lots of steels. They thaw aluminum efficiently. They deal with copper and copper alloys. They help rare-earth elements as well. The robust design supports heavy tons. Also the big 500kg crucible remains strong. It stands up to fracturing under anxiety.

Excellent thermal conductivity is very important. This product transfers heat properly. Your heater thaws steel quicker. This saves energy. It increases efficiency. The smooth internal surface area helps as well. Molten steel pours out cleanly. Less metal sticks inside. You shed less material.

Select the appropriate dimension for your heater. The 30kg and 40kg suit smaller operations. The 100kg and 200kg in shape medium factories. The big 500kg crucible serves heavy industry. All sizes deliver trustworthy efficiency. Expect regular results set after batch.

These crucibles indicate less downtime. Their toughness protects against abrupt failings. You avoid pricey furnace fixings. They use excellent value in time. Substitutes take place much less commonly. Prepare yourself for reliable, trustworthy metal melting.

(silicon carbide clay ceramic graphite melting pot crucible 30kg 40kg 100kg 200kg 500kg for induction furnace melting metal)

Applications of silicon carbide clay ceramic graphite melting pot crucible 30kg 40kg 100kg 200kg 500kg for induction furnace melting metal

Silicon carbide clay ceramic graphite crucibles handle intense induction heater melting flawlessly. These pots combine silicon carbide, clay, and graphite. This mix develops an extremely tough product. Induction heating systems warmth steel quick utilizing magnetic fields. Normal crucibles often fracture under this abrupt, severe warmth. These silicon carbide clay graphite pots stand up to thermal shock far better. They will not fracture conveniently when you put warm metal or include cold cost product.

Warm relocations quickly with these crucibles. This suggests your heating system thaws metal quicker. You conserve energy and time. The material also eradicates chemical attack. It deals with extreme chemicals from dissolved metals like iron, copper alloys, light weight aluminum, and brass. This resistance makes the crucible last much longer. You obtain even more thaws prior to changing it. That conserves money with time.

We provide these crucibles in several sizes. You can find 30kg, 40kg, 100kg, 200kg, and 500kg abilities. Choose the dimension matching your heater and set requirements. The 30kg and 40kg pots fit smaller procedures. The 100kg, 200kg, and 500kg dimensions fit larger foundries thawing bigger quantities. These crucibles work dependably for several steels. They are strong choices for melting gold, silver, platinum also. Their stamina handles the constant home heating and cooling cycles in busy foundries. You need dependable devices for constant melting. This material provides regular performance.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of silicon carbide clay ceramic graphite melting pot crucible 30kg 40kg 100kg 200kg 500kg for induction furnace melting metal

Here are five common questions about our silicon carbide clay ceramic graphite melting pot crucibles (30kg, 40kg, 100kg, 200kg, 500kg) for induction furnace metal melting:

What material is the crucible made from? The crucible combines silicon carbide, clay ceramic, and graphite. This mix gives excellent heat resistance. It handles extreme heat well. This makes it last longer. It also handles quick temperature changes without cracking easily. These properties are vital for melting metals repeatedly.

What temperature can this crucible handle? Our crucibles withstand very high temperatures. They operate safely up to 1650°C (around 3000°F). This suits melting most common metals like aluminum, copper alloys, and zinc. Always check the specific metal’s melting point first. Do not exceed the crucible’s maximum temperature rating.

How do I choose the right size (30kg, 40kg, 100kg, 200kg, 500kg)? Pick the size matching your furnace capacity and your typical metal batch weight. The number (like 30kg) shows the approximate molten metal weight it holds. Using a crucible too large or too small for your furnace reduces efficiency. It can also shorten the crucible’s life. Check your furnace manufacturer’s recommendations.

How long does one crucible typically last? Crucible lifespan varies greatly. It depends on the metals melted, the temperatures reached, how often cycles happen, and general handling. Proper use and careful operation extend life. Expect many melting cycles under normal conditions. Watch for signs of wear like cracks or thinning walls. Replace it when these appear.

Do I need to preheat the crucible before use? Yes, preheating is essential. Always preheat a new crucible slowly and evenly. Do this before its first melt. Preheating removes any moisture. It prevents thermal shock. Thermal shock causes cracks. Follow the specific preheating schedule provided with the crucible. Never skip this step.

(silicon carbide clay ceramic graphite melting pot crucible 30kg 40kg 100kg 200kg 500kg for induction furnace melting metal)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Silicon Carbide Graphite Crucible 50kg for Melting Aluminum Copper

100#120#150#200#350#40#60#80#8ml Reaction sintering ceramic SIC silicon carbide ceramic crucible

1kg 2kg 3kg graphite crucible filling silicon carbide graphite crucible

High Quality Best Induction Melting Molybdenum crucible

Good Quality Factory 50kg 250kg Sic Silicon Carbide Sagger Graphite Crucible for Melting