Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(SIC Silicon Carbide Graphite Crucible for Copper Melting)

Specification of SIC Silicon Carbide Graphite Crucible for Copper Melting

This SIC silicon carbide graphite crucible handles copper melting well. It combines silicon carbide and graphite materials. This mix gives strong performance in high heat situations. The crucible withstands very high temperatures. Copper melts around 1085°C. This crucible works safely far above that point. It handles temperatures over 1600°C easily.

Thermal shock resistance is a key benefit. Crucibles heat up fast. They also cool down quickly sometimes. Sudden temperature changes stress materials. This crucible resists cracking from those shocks. It lasts longer because of this strength. Frequent heating and cooling cycles are less damaging.

Chemical resistance is vital for copper melting. Molten copper is aggressive. It attacks many materials. This crucible resists corrosion from molten copper. It keeps its shape and integrity. Contamination of the melt is minimized. Your copper stays cleaner.

Mechanical strength is high. The crucible feels solid. It resists bumps and impacts during handling. This toughness reduces breakage risk. Operators can move it safely. Lifespan increases with careful use.

Heat transfer is efficient. The material conducts heat well. Melting times are faster. Energy use is lower. You save on power costs. Temperature control is also easier. Uniform heating happens throughout the crucible.

The surface is smooth. Slag and dross don’t stick badly. Cleaning between melts is simpler. Crucible maintenance takes less time. Downtime for your furnace reduces.

This crucible fits standard copper melting furnaces. Common induction and resistance furnaces use it. Crucible dimensions follow typical industry sizes. Capacity options exist for different batch needs.

(SIC Silicon Carbide Graphite Crucible for Copper Melting)

Applications of SIC Silicon Carbide Graphite Crucible for Copper Melting

These silicon carbide graphite crucibles are built tough for melting copper. Copper melts at very high temperatures. This demands a crucible that won’t crack or fail. Silicon carbide graphite handles this intense heat perfectly. It withstands the molten copper’s heat without breaking down.

These crucibles resist thermal shock well. Foundries heat them up fast. They also cool them down fast. Sudden temperature changes stress materials. Silicon carbide graphite handles these changes better than many other materials. This means fewer cracks and a longer working life. Your crucible lasts longer.

Slag buildup is a common problem in copper melting. Slag sticks to the crucible walls. Silicon carbide graphite has a very smooth surface. Molten slag doesn’t stick to it easily. This makes cleaning much simpler. You spend less time cleaning and more time melting. Crucible maintenance becomes easier.

Copper purity matters greatly. Impurities ruin the final product. Silicon carbide graphite is inert. It doesn’t react chemically with the molten copper. The melt stays clean. You get high-purity copper every time. Metal quality is consistent.

These crucibles transfer heat efficiently. They heat up quickly. This saves energy. Your furnace uses less power. Operating costs go down. Foundry workers like them. They are reliable under tough conditions. The crucible performs consistently batch after batch. Downtime reduces. Production increases.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of SIC Silicon Carbide Graphite Crucible for Copper Melting

Here are five common questions about SIC Silicon Carbide Graphite Crucibles for copper melting:

What makes these crucibles good for melting copper?

These crucibles combine silicon carbide and graphite. This mix gives them great strength and resistance to heat shock. Copper melts at high temperatures. These crucibles handle that heat well. They resist cracking when heated fast or cooled quickly. This is important for foundry work.

How long do these crucibles last?

They last much longer than regular clay or graphite crucibles. Silicon carbide is very hard. It resists wear from stirring and pouring molten copper. The graphite helps with heat transfer and thermal shock resistance. Expect many more melting cycles compared to cheaper options. This saves money over time.

What temperature can they handle?

These crucibles work fine well above copper’s melting point. Copper melts around 1085°C (1985°F). These crucibles easily handle temperatures over 1600°C (2912°F). This gives you a big safety margin. You don’t need to worry about the crucible failing during normal copper melting operations.

Why don’t they react with molten copper?

The silicon carbide forms a protective layer. This layer stops the molten copper from sticking to the crucible walls. It also prevents chemical reactions. Copper won’t alloy with the crucible material. This keeps your copper melt pure. You get clean pours without contamination.

How should I handle and care for them?

Handle them carefully. Avoid hard impacts. Dry them completely before first use. Preheat new crucibles slowly to remove moisture. Always preheat before adding solid copper. Avoid sudden temperature changes. Let the crucible cool down slowly after use. Store them in a dry place. Proper care maximizes their lifespan.

(SIC Silicon Carbide Graphite Crucible for Copper Melting)

REQUEST A QUOTE

RELATED PRODUCTS

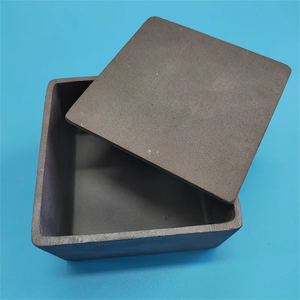

Square rectangular shape laboratory refractory Ceramic Crucible

1kg 2kg 3kg Graphite crucible For Gold Melting Crisol De Grafito

High Temperature Resistant Silicon Carbide Sagger SISIC RSIC Graphite Ceramic Crucible

Graphite crucible With 27cm Diameter And 30 Cm Heigh Graphite-crucibl

1650C SIC silicon carbide cylinder crucible