Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

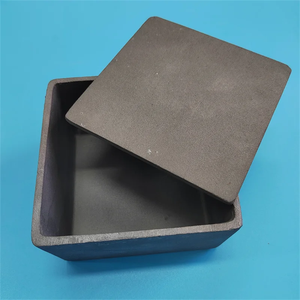

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal)

Specification of 30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal

These crucibles handle massive steel melting work. They are available in 30kg, 50kg, 60kg, and 100kg capacities. You need this size for significant foundry job or big recycling operations. The product is silicon carbide blended with graphite. This mix is essential. It provides you leading performance melting difficult metals like cast iron, steel, copper alloys, and aluminum.

The silicon carbide graphite blend is really solid. It resists severe heat. Crucibles face temperatures over 1500 ° C regularly. This material handles it. It also withstands thermal shock well. Crucibles heat up quickly and cool off repeatedly. Abrupt temperature changes can crack weak materials. These stand up. They are extra long lasting than clay-graphite crucibles. You obtain longer service life. That saves money over time.

These crucibles transfer warm successfully. You melt metal faster. That conserves energy. It speeds up your manufacturing cycles. The smooth internal surface is very important. It avoids metal from sticking. It makes pouring cleaner. You get much less slag build-up as well. This indicates less cleansing between melts. It maintains your steel pure.

Dealing with these large crucibles requires treatment. Usage appropriate tongs developed for the dimension. Raise them correctly. Never ever place a hot crucible on a cold or damp surface. Thermal shock is still a danger. Constantly preheat a new crucible gradually before very first usage. This drives out any type of wetness. It conditions the material. Follow the supplier’s pre-heating routine precisely. Shop crucibles in a completely dry location. Secure them from impacts. Chips or cracks damage the framework. Safety and security gear is necessary. Put on heat-resistant handwear covers and face security constantly.

(30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal)

Applications of 30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal

Durable silicon carbide graphite crucibles take care of difficult melting work. These crucibles can be found in large sizes like 30kg, 50kg, 60kg, and 100kg capabilities. They are best for melting actors iron metal. Shops and steel workshops use them daily. Cast iron demands heats. These crucibles deliver. Their silicon carbide graphite mix stands up to extreme heat. It manages abrupt warmth changes well. This protects against cracking. Melting actors iron produces slag. This slag is corrosive. The crucible product resists chemical attack. Your crucible lasts longer.

Selecting the best size matters. A 30kg crucible helps smaller sized batches. It fits induction heating systems well. A 50kg or 60kg crucible manages medium manufacturing runs. These sizes equilibrium capacity and furnace fit. The big 100kg crucible fits big foundries. It thaws large quantities of iron quick. Efficiency improves. Workers require the appropriate lifting equipment. Taking care of these hefty crucibles safely is crucial. Constantly utilize tongs made for the crucible dimension.

These crucibles get to the warmth needed for actors iron. They function well in induction heaters. They additionally operate in gas or oil-fired heating systems. Constant efficiency is critical. You obtain trustworthy melting cycles. Less downtime takes place. The product conducts warm successfully. Energy costs remain reduced. Durability is a major benefit. Yes, they cost even more upfront. Their extreme longevity saves money later on. You change crucibles less often. Much less upkeep is required. Manufacturing keeps moving. They take care of the physical anxiety of pouring molten iron. Depend on them for demanding foundry work.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal

What makes silicon carbide graphite crucibles good for melting cast iron?

Cast iron melts at very high temperatures. Silicon carbide graphite handles this heat well. It resists the extreme temperatures needed. It also fights chemical attack from molten iron. This material lasts longer than clay or steel crucibles. It saves money over time.

What’s the maximum temperature these large crucibles can take?

These crucibles handle continuous use around 1600°C (2912°F). They can briefly tolerate peaks near 1700°C (3092°F). Never exceed the manufacturer’s specific rating. Going too hot damages the crucible fast. Check the specs for your exact model.

How many melting cycles can I expect from a 30kg, 50kg, 60kg, or 100kg crucible?

Lifespan varies a lot. Crucible size, furnace type, metal melted, and operator skill matter. A 30kg crucible might last 15-30 cycles. A 100kg crucible might manage 10-20 cycles. Proper care extends life significantly. Expect fewer cycles with rough handling or overheating.

Are special handling tools needed for these heavy crucibles?

Yes. These crucibles are extremely heavy and brittle. Always use proper tongs designed for the crucible size and shape. Never handle a hot crucible without correct tools. Use lifting equipment for the 60kg and 100kg sizes. Mishandling causes cracks or breaks.

Is preheating the crucible necessary before the first use?

Yes. Preheating is critical. It removes any absorbed moisture slowly. Skip this step and thermal shock happens. The crucible can crack or explode. Heat it gradually to around 200°C (392°F) minimum. Follow the manufacturer’s preheating schedule exactly.

(30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal)

REQUEST A QUOTE

RELATED PRODUCTS

Silicon carbide graphite crucible static pressure forming metal smelting

Large Smelting Furnace Silicon Sizes Melting Carbide Crucible Steel Clay Cast Sic 100kg Iron Graphite Crucibles for

High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

Silicon carbide graphite crucible for all kinds of metal casting melting

Customized silicon carbide crucibles s