Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

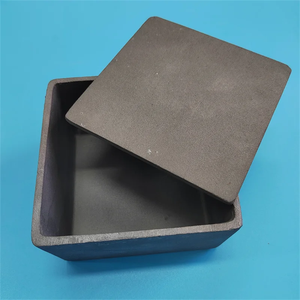

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation)

Specification of Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation

The Ceramic Crucible Silicon Carbide (SiC) Ceramic Crucible SIC is made for high-temperature home heating and volatilization procedures. This item is made from premium silicon carbide material. It offers excellent thermal stability and toughness. The crucible handles severe temperature levels approximately 1600 ° C. It resists sudden temperature modifications without fracturing. This makes it ideal for duplicated home heating and cooling down cycles.

The product has high chemical inertness. It holds up against rust from acids, antacid, and molten metals. This ensures minimal contamination during experiments or commercial applications. The dense structure stops leaks or responses with examples. It maintains purity in sensitive processes like steel smelting or chemical analysis.

Mechanical toughness is an essential attribute. The crucible resists physical wear and effect. It maintains structural honesty under hefty loads or mechanical tension. This extends its service life compared to traditional ceramic or graphite options. The surface is smooth and non-porous. This streamlines cleansing and reduces deposit accumulation.

The design consists of a consistent wall density. It advertises even warmth circulation for constant outcomes. The form is optimized for compatibility with basic research laboratory furnaces and industrial equipment. Several sizes are offered to fit various example quantities. Custom-made dimensions can be created upon request.

Applications consist of metallurgy, chemistry, products research study, and electronic devices manufacturing. It is optimal for melting, calcining, or vaporizing substances at heats. The crucible functions well in environments calling for accuracy and dependability. Its reduced thermal development coefficient reduces deformation dangers.

Upkeep is straightforward. Users should stay clear of thermal shocks beyond defined limits. Cleansing with non-abrasive products protects the surface top quality. Correct handling makes sure long-lasting efficiency. Replacement frequency is minimized because of robust building.

The item fulfills market criteria for security and performance. It is checked for performance under real-world problems. Each system undertakes quality checks prior to delivery. Technical assistance is offered for use standards or modification needs.

(Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation)

Applications of Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation

Ceramic crucibles constructed from silicon carbide (SiC) serve high-temperature processes like home heating and volatilization. These crucibles handle extreme warmth without fracturing. They transfer heat swiftly, spread it equally, and withstand sudden temperature changes. This sturdiness makes them last longer than options.

Labs and markets utilize SiC crucibles for tasks needing exact warmth control. Labs use them to vaporize examples safely. Steel handling plants thaw metals in them. Semiconductor makers utilize them to take care of pure products. The crucibles resist responses with acids, alkalis, or corrosive materials. This maintains procedures contamination-free.

Various other materials like quartz or alumina often stop working under thermal tension. SiC crucibles make it through quick home heating and cooling cycles. Fewer substitutes suggest reduced prices over time. Upkeep remains easy. Customers clean them with common techniques. Right handling expands their lifespan.

These crucibles prevent contamination throughout unstable compound home heating. Purity matters in fields like pharmaceuticals. SiC surfaces stay non-reactive, preventing undesirable blending. Also small impurities get obstructed.

SiC crucibles fit heaters, kilns, and custom-made setups. They stand up to temperature levels beyond 1600 ° C. Their durability fits rough industrial settings. Companies pick them for dependability in vital procedures. Power performance enhances due to quick warm transfer. Much less power is squandered.

Dealing with unstable materials securely is another benefit. SiC’s security protects against leakages or reactions. This decreases risks in procedures involving combustible or reactive materials. Employees operate with higher self-confidence.

Cost-effectiveness originates from lengthy service life and reduced upkeep. Industries save on regular purchases and downtime. Efficiency remains constant throughout batches. This dependability supports large-scale production requirements.

The crucibles operate in diverse settings, from research laboratories to hefty market. Their flexibility meets particular heating needs. Customized shapes or sizes are feasible. This flexibility addresses one-of-a-kind task demands.

SiC’s mechanical strength includes worth. It resists physical wear during handling or processing. Rough industrial usage creates marginal damage. This decreases waste and boosts operations effectiveness.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation

Ceramic crucibles made from silicon carbide (SiC) handle high-temperature tasks like heating and volatilization. Here are 5 common questions about these crucibles. What are SiC ceramic crucibles made of? They combine silicon carbide with ceramic binders. This mix creates a material that withstands extreme heat and resists damage. The structure stays stable even under rapid temperature changes. Why pick SiC crucibles for heating volatilization? These crucibles conduct heat well. They spread heat evenly to avoid hot spots. This ensures substances vaporize consistently. Volatilization requires precise control, and SiC crucibles deliver reliability. How hot can they get? Most SiC crucibles work up to 1600°C. Specific grades tolerate higher temperatures. Check the product details before use. Exceeding limits risks cracks or breaks. Do SiC crucibles resist chemicals? Yes. They handle acids, alkalis, and molten metals. Reactions during volatilization often involve corrosive materials. SiC crucibles minimize contamination and degradation. This makes them last longer than alternatives like graphite or alumina. How long do SiC crucibles last? Durability depends on usage. Proper care extends their lifespan. Avoid sudden temperature swings. Clean residues after each use. Inspect for cracks or wear regularly. With good maintenance, they outperform many other materials.

(Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation)

REQUEST A QUOTE

RELATED PRODUCTS

KERUI Factory Customized Silicon Carbide Graphite Crucible with Quantity

MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for

High Temperature Clay Silicon Carbide Graphite Crucible For Melting Steel

China Factory 100kg High Heats Silicon Carbide Crucible TT

Silicon carbide crucible for melting aluminum