Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

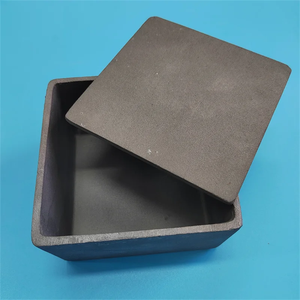

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Factory supply high temperature resistance silicon carbide graphite crucible clay graphite crucible for melting)

Specification of Factory supply high temperature resistance silicon carbide graphite crucible clay graphite crucible for melting

This crucible manages severe warmth. It thaws steels well. Factories make it for shops and steel employees. The mix uses silicon carbide, graphite, and special clay. This mix develops solid warmth resistance. It stands up to temperature levels much past numerous other crucibles. Sudden temperature changes cause much less tension cracks. This crucible lasts longer under challenging problems.

Its structure is thick and tough. This thickness quits liquified steel taking in. It shields the crucible. It keeps the steel pure. You see much less disintegration and matching within. Upkeep becomes less complicated. The crucible carries out reliably batch after set. Downtime lowers.

Utilize it for thawing various metals. It benefits gold, silver, copper, brass, light weight aluminum. It manages alloys also. The crucible suits furnace use. It also collaborates with lantern melting. Its form advertises good heat flow. Thawing happens faster. Energy usage might lower.

Different sizes are readily available. Typical forms are A, B, and C types. Sizes vary from little lab to huge commercial. Ability varies from a few ounces to lots of kgs. Pick the size fitting your heating system and metal set. The crucible walls are thick sufficient for strength. They stay thin sufficient for efficient home heating.

Quality assurance occurs throughout manufacturing. Each crucible gets checked. Workers try to find fractures or defects. They test material thickness. Product packaging makes use of solid materials. Crates or cartons protect against delivery damages.

(Factory supply high temperature resistance silicon carbide graphite crucible clay graphite crucible for melting)

Applications of Factory supply high temperature resistance silicon carbide graphite crucible clay graphite crucible for melting

Factory supply silicon carbide graphite crucibles take care of severe heat. These crucibles are tough. They help melting many metals. Individuals use them in different industries. Jewelers melt gold and silver. These crucibles work well. The crucible won’t break quickly. Factories thaw light weight aluminum and brass. They require crucibles that last. Silicon carbide graphite crucibles are excellent here. They stand up to chemical reactions too. This keeps the liquified steel cleaner. Iron shops use them sometimes. The crucibles withstand the heats. They are good for smaller sized iron sets. Copper alloys thaw in them also. Bronze and brass thaw effectively. The crucible product does not pollute the steel. Crucibles are vital in steel recycling. They melt scrap steel successfully. Their strength aids them endure repeated heating and cooling. This saves money long term. Laboratories utilize these crucibles. They melt samples for screening. The crucible’s stability is important for precise results. Individuals utilize them for melting zinc also. Zinc needs mindful handling. The crucible offers trusted performance. Steel mills often utilize them for specialty alloys. The crucible takes care of the intense warm required. Ceramic lusters obtain thawed in them occasionally. Potters find them beneficial. They are better than basic clay crucibles. They last much longer under high heat. Investment spreading shops rely upon them. They melt the metal for accurate molds. The crucible delivers consistent results.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory supply high temperature resistance silicon carbide graphite crucible clay graphite crucible for melting

Factory Supply High Temperature Resistance Silicon Carbide Graphite Crucible / Clay Graphite Crucible for Melting – FAQs

What are these crucibles used for?

These crucibles melt metals. People use them for gold, silver, copper, aluminum, and other metals. Factories, jewelers, and foundries rely on them. They handle the intense heat needed for melting.

Why pick silicon carbide graphite or clay graphite crucibles?

Their big advantage is heat resistance. They withstand incredibly high temperatures without breaking down. This is crucial for melting metals safely and efficiently. They won’t crack or warp easily under heat stress.

How long do these crucibles last?

They last much longer than basic clay crucibles. The silicon carbide graphite mix offers superior durability. The clay graphite version is also very tough. You get many more melts before needing a replacement. This saves money over time.

What sizes are available?

We offer many sizes. Crucibles come small for jewelry work. They come large for industrial foundry use. You can find the right capacity for your specific melting job. Check our product list for exact dimensions and volume.

How should I handle and care for them?

Handle them carefully. Avoid bumps or drops. Always preheat a new crucible slowly before its first full melt. This prevents thermal shock cracks. Let the crucible cool down naturally after use. Don’t quench it in water. Store them in a dry place.

(Factory supply high temperature resistance silicon carbide graphite crucible clay graphite crucible for melting)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Silicon Carbide Ceramic Crucible Graphite Crucible

Custom Clay Graphite Crucible Graphite Vacuum Crucible With Lid High Purity Graphite Crucible

Custom Factory Supply Industry Grade Silicon Carbide Graphite Crucible

KERUI Factory Customized Silicon Carbide Graphite Crucible with Quantity

Good Quality Factory 50KG 250KG Sic Crucibles Silicon Carbide Sagger Graphite Crucible For Melting