Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

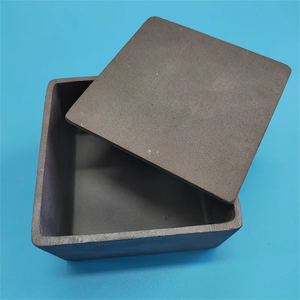

(Graphite Clay crucible Graphite crucible For Casting Gold)

Specification of Graphite Clay crucible Graphite crucible For Casting Gold

Graphite clay crucibles, especially created for casting gold and other rare-earth elements, are high-performance melting vessels crafted from a blend of premium natural graphite and refractory clay. These crucibles excel in high-temperature applications, offering phenomenal thermal conductivity, resistance to thermal shock, and resilience. Ideal for jewelers, jewelers, and small foundries, they make sure reliable steel melting while maintaining pureness and architectural integrity.

** Product Structure **: The crucibles are made from a blend of high-purity graphite (70-80%) and heat-resistant clay (20-30%), producing a robust framework efficient in standing up to severe temperature levels approximately 1600 ° C(2912 ° F). The graphite ensures fast, also warmth distribution, while the clay boosts mechanical stamina and resistance to breaking.

** Thermal Characteristics **: These crucibles include exceptional thermal shock resistance, allowing fast cooling and heating without damage. Their low thermal expansion coefficient decreases tension during temperature level fluctuations. The fine-grained graphite framework boosts warm retention, minimizing power consumption during extended melting sessions.

** Physical Requirements **: Readily available in capabilities ranging from 1 kg to 20 kg, common sizes include heights of 4– 12 inches and sizes of 3– 8 inches. Wall surface thickness varies between 5– 15 mm for optimum warmth transfer and longevity. The crucibles are light-weight (200– 1500 grams, relying on size) and designed with a tapered shape for simple putting and slag splitting up.

** Chemical Resistance **: Resistant to oxidation and slag development, the crucibles avoid contamination of molten gold. The non-reactive surface makes sure high-purity casts, critical for jewelry and investment-grade gold products.

** Applications **: Mostly utilized for melting gold, silver, platinum, and non-ferrous alloys. Ideal for induction furnaces, lp lanterns, and electrical melters. Perfect for casting ingots, precious jewelry elements, and dental alloys.

** Handling & Maintenance **: Preheat gradually to 200 ° C (392 ° F) before very first usage to remove dampness. Avoid abrupt temperature level adjustments. Tidy residues after each use with a dry brush. With appropriate care, life-span arrays from 20– 50 melts, depending on operating problems.

** Safety and security **: Use heat-resistant handwear covers and tongs throughout handling. Ensure the crucible is placed on a secure, fireproof base throughout heating. Shop in a dry setting to avoid wetness absorption.

** Qualification **: Produced to meet market requirements for metallurgical applications, ensuring regular top quality and efficiency.

These graphite clay crucibles integrate reliability, performance, and longevity, making them indispensable for accuracy gold casting and high-temperature metalworking.

(Graphite Clay crucible Graphite crucible For Casting Gold)

Applications of Graphite Clay crucible Graphite crucible For Casting Gold

Graphite clay crucibles are vital devices in the melting and spreading of rare-earth elements like gold, silver, and platinum. Crafted from a mix of high-purity graphite and refractory clay, these crucibles integrate the superior thermal conductivity of graphite with the architectural stamina and longevity of clay. This one-of-a-kind composition allows them to stand up to severe temperature levels– up to 1600 ° C (2912 ° F)– while resisting thermal shock, making them perfect for duplicated home heating and cooling cycles throughout metalworking procedures. Their non-reactive nature makes sure that molten steels stay unpolluted, protecting the pureness and high quality of gold throughout spreading.

Designed for flexibility, graphite clay crucibles are widely utilized in jewelry production, oral labs, and commercial refining. Jewelers rely upon them for precision casting of detailed gold styles, while dental laboratories use them to create alloys for crowns and bridges. In commercial settings, these crucibles deal with large-scale gold refining and recycling. They are compatible with different heating system kinds, including electric, gas, and induction heaters, providing adaptability across different applications. Readily available in numerous sizes, they cater to small-scale artisans and high-volume factories alike.

A key benefit of graphite clay crucibles is their performance. The high thermal conductivity of graphite guarantees quick, even warm distribution, decreasing melting energy and time intake. Their durable building reduces wear, providing a much longer life expectancy contrasted to ceramic or steel choices. This longevity equates to cost financial savings gradually, as less replacements are needed. Additionally, the smooth indoor surface of these crucibles allows for simple putting and cleanup, enhancing workflow effectiveness.

Proper treatment is vital for ideal performance. Individuals must pre-heat crucibles slowly to remove wetness and avoid cracking. Preventing sudden temperature modifications and utilizing proper tongs throughout managing further prolongs their life. After use, deposits ought to be eliminated to keep purity in succeeding thaws. By following these practices, specialists make sure regular outcomes and maximize the crucible’s durability.

In recap, graphite clay crucibles are important for any individual working with high-value metals like gold. Their heat resistance, longevity, and purity preservation make them a trusted selection for accomplishing specific, high-quality casts in both artistic and commercial contexts. Purchasing these crucibles guarantees performance, cost-effectiveness, and remarkable outcomes in steel casting procedures.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Graphite Clay crucible Graphite crucible For Casting Gold

What is the maximum temperature a graphite clay crucible can withstand for casting gold?

Graphite clay crucibles typically withstand temperatures up to 1600°C (2912°F), making them ideal for melting gold, which has a melting point of around 1064°C (1947°F). Their high thermal stability ensures safe and efficient melting without cracking or degrading under standard gold-casting conditions.

How long does a graphite crucible last when used for gold casting?

With proper care, a graphite crucible can last 20-50 uses, depending on operating temperatures, handling, and cooling practices. Avoid rapid temperature changes, overfilling, or direct flame contact to extend its lifespan. Regular inspection for cracks or wear is recommended to ensure safety and performance.

Is a graphite crucible safe for melting pure gold?

Yes, graphite crucibles are chemically inert and non-reactive with molten gold, preventing contamination. They are widely used in jewelry making and refining due to their purity and ability to maintain the integrity of precious metals. Ensure the crucible is clean and free of residues from previous uses to avoid impurities.

How do I clean a graphite crucible after melting gold?

Allow the crucible to cool completely after use. Gently remove any leftover gold residue with a soft brush or non-abrasive tool. Avoid water or harsh chemicals, as sudden cooling or corrosive agents can damage the graphite. For stubborn residues, heat the crucible slightly to loosen debris before brushing.

Why choose a graphite crucible over ceramic or steel for gold casting?

Graphite crucibles offer superior thermal conductivity, faster heating, and better heat distribution compared to ceramic or steel. They are lighter, more durable under high temperatures, and less prone to thermal shock. Unlike steel, graphite doesn’t oxidize or interact with molten gold, ensuring a purer melt and longer usability.

(Graphite Clay crucible Graphite crucible For Casting Gold)

REQUEST A QUOTE

RELATED PRODUCTS

2024 Hot 1KG 3KG 5KG Single Ring Graphite Crucible With Ceramic For Gold Silver Precious Metal Melting

Customized Silicon Carbide SiC Ceramic Puffco Cup Ssic Insert Heating Crucible

Graphite crucible With 27cm Diameter And 30 Cm Heigh Graphite-crucibl

Iron Large Graphene 500kg Refractory Copper Furnace Sizes Carbide Melting 100kg Metal Silicon Carbon Crucible

Square rectangular shape laboratory refractory Ceramic Crucible