Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

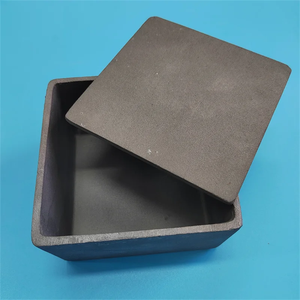

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass)

Specification of High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass

High Carbon Graphite Crucibles and Sic Silicon Carbide Crucibles serve important duties in high-temperature melting processes. These devices handle materials like gold, brass, copper, and glass effectively. The High Carbon Graphite Crucible stands out for its warm resistance. It tolerates severe temperature levels as much as 3000 ° C. This makes it suitable for repeated usage in heating systems. The material consists of thick graphite with extra carbon. This structure avoids fractures under fast home heating. It also stands up to oxidation and chemical disintegration from liquified metals. The crucible warms evenly and cools down swiftly. This makes sure regular cause metal casting or alloy blending. Its smooth indoor surface area lowers sticking. Cleaning ends up being simpler after each use. Upkeep needs very little effort. Operators discover it reputable for commercial or small-scale operations.

The Sic Silicon Carbide Crucible offers superior durability. It combines silicon carbide with bonded clay. This mix enhances toughness and thermal shock resistance. The crucible functions well in temperature levels reaching 1600 ° C. Sudden temperature level changes trigger no damages. This fits environments with regular heating and cooling cycles. Its inflexible structure resists abrasion from mixing or putting. The material does not respond with most metals or glass. This protects pureness throughout melting. Customers report longer life span contrasted to conventional alternatives. The crucible works in electric or gas-fired heaters. Installment and handling stay uncomplicated.

Both crucibles focus on safety and security. They lessen risks of breakage or leaks. Stable efficiency lowers downtime in manufacturing. Picking in between them depends upon details requirements. High Carbon Graphite matches greater temperature level applications. Sic Silicon Carbide masters rugged problems. Appropriate preheating prolongs their life expectancy. Customers ought to follow guidelines for heating rates. Storing crucibles in completely dry problems stops moisture damage. These products satisfy needs throughout jewelry production, factories, and glass studios. They deliver precision and dependability for experts.

(High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass)

Applications of High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass

High carbon graphite crucibles and silicon carbide (SiC) crucibles offer crucial roles in high-temperature melting procedures. These devices handle steels like gold, brass, copper, and products like glass effectively. Both types stand up to extreme warm yet vary in homes.

High carbon graphite crucibles excel in sturdiness. They withstand thermal shock and corrosion. This makes them optimal for repeated melting cycles. Their high thermal conductivity makes sure also warmth distribution. Metals thaw much faster, lowering energy usage. Graphite crucibles work well with non-ferrous steels. Gold and copper thaw easily without contamination. These crucibles are cost-efficient for small operations. Maintenance is simple. Customers clean them quickly after cooling.

Silicon carbide crucibles offer higher stamina. They deal with temperatures beyond 1600 ° C. Their structure protects against cracking under fast temperature level adjustments. This matches industrial setups with constant cooling and heating. SiC crucibles last longer than graphite under heavy usage. They are favored for melting brass and glass. Brass calls for regular heat, and SiC keeps stability. Glass melting demands reduced reactivity, and SiC protects against contaminations. These crucibles are heavier yet offer much better warmth retention.

Both crucible types secure product pureness. They prevent metal oxidation during melting. This makes sure premium results. Graphite is lighter, making it simpler to handle by hand. SiC suits automated systems due to its toughness. Users choose based on melting regularity and material kind.

Security is a concern. Proper preheating prolongs crucible life. Unexpected temperature level spikes damages crucibles in time. Customers comply with standards to avoid cracks. Storage space in completely dry conditions stops wetness absorption.

These crucibles are made use of in precious jewelry production, steel recycling, and glassblowing. Their dependability supports regular manufacturing. Expenses vary, but lasting savings come from lowered replacements. Personalized sizes are readily available for specialized needs. Suppliers supply technological assistance for optimum usage.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass

High Carbon Graphite Crucibles and Sic Silicon Carbide Crucibles are tools for melting metals like gold, brass, copper, and glass. Here are answers to common questions:

1. What materials are these crucibles made from?

High Carbon Graphite Crucibles use high-purity graphite mixed with binders. Sic Silicon Carbide Crucibles combine silicon carbide with graphite or other additives. Both materials handle extreme heat.

2. What temperatures can they withstand?

High Carbon Graphite Crucibles work up to 3000°F. Sic Silicon Carbide Crucibles handle higher temperatures, around 3200°F. They stay stable without cracking.

3. Why choose these crucibles for melting metals?

They resist thermal shock. Sudden temperature changes don’t damage them. They don’t react with molten metals or glass. This keeps the melted material pure.

4. How long do these crucibles last?

Lifespan depends on usage. High Carbon Graphite lasts 10-20 melts. Sic Silicon Carbide lasts longer, often 30-50 melts. Proper heating and cooling extend durability.

5. How to maintain them?

Clean after each use. Remove leftover metal or slag. Avoid dropping or hitting them. Let them cool slowly. Store in a dry place to prevent moisture damage.

(High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass)

REQUEST A QUOTE

RELATED PRODUCTS

Most Popular High Temperature Heating Crucible Tungsten Crucibles

Best 99.95% Purity Molybdenum Crucible For Melting

R High temperature resistance graphite crucible 20kg 50kg high pure 100kg silicon carbide graphite crucible for melting metal

High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal

Silicon Carbide Graphite Crucible/gold silver smelting graphite / non-ferrous and noble metals smelting/Jewelry