Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

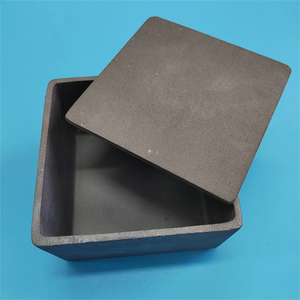

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible)

Specification of High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible

The High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible is engineered for extreme thermal and chemical settings, incorporating silicon carbide (SiC) and high-purity graphite to provide unmatched durability and efficiency. Ideal for steel melting, glassworking, and high-temperature chemical processing, this crucible masters applications needing resistance to aggressive acids, antacid, molten metals, and oxidizing environments.

** Product Make-up **: The crucible is composed of 50-70% silicon carbide and 20-30% premium graphite, bound with advanced porcelains for structural integrity. Silicon carbide gives remarkable firmness and thermal conductivity, while graphite enhances thermal shock resistance and decreases wettability by molten metals.

** Trick Requirements **:.

– ** Maximum Operating Temperature **: 1600 ° C( 2912 ° F) in oxidizing environments and as much as 1800 ° C( 3272 ° F) in inert or minimizing ambiences.

– ** Thermal Shock Resistance **: Withstands fast temperature fluctuations (ΔT > 500 ° C) without breaking.

– ** Thickness **: 2.6-2.8 g/cm ³, making sure high mechanical stamina and decreased disintegration.

– ** Porosity **: <15%, minimizing penetration by corrosive substances.

- **Compressive Strength**: >< 15 %, decreasing penetration by harsh materials.- ** Compressive Toughness **: > 80 MPa, appropriate for sturdy commercial use.

– ** Chemical Resistance **: Resists strike from acids (HCl, HNO ₃, H ₂ SO ₄), antacid (NaOH, KOH), liquified light weight aluminum, copper, zinc, and slag.

** Applications **: Designed for shops, laboratories, and aerospace markets, it is optimal for melting non-ferrous steels (aluminum, brass, bronze), rare-earth elements, and alloys. It additionally offers in chemical synthesis, driver production, and warmth therapy processes.

** Benefits **:.

– ** Extended Life Expectancy **: Outshines conventional clay or ceramic crucibles by 3-5x as a result of superior oxidation and deterioration resistance.

– ** Power Effectiveness **: High thermal conductivity makes certain faster heating and consistent temperature level distribution, reducing energy usage.

– ** Low Contamination **: Non-reactive surface maintains purity of thaws, essential for high-precision spreading and semiconductor applications.

– ** Eco-Friendly **: Durable construction reduces waste and replacement regularity.

** Safety and security & Handling **: Preheated before initial usage to eliminate wetness. Compatible with induction and gas furnaces. Avoid abrupt cooling and straight fire contact.

This crucible is a cost-efficient remedy for industries prioritizing longevity, thermal effectiveness, and reliability under severe conditions. Its durable design makes certain regular performance, reducing downtime and functional expenses.

(High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible)

Applications of High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible

High Rust Resistance and Oxidation Resistance Silicon Carbide Graphite Crucibles are crafted to excel in severe commercial atmospheres, combining the toughness of silicon carbide with the thermal stability of graphite. These crucibles are ideal for applications calling for prolonged direct exposure to heats, harsh materials, and oxidative conditions, guaranteeing dependability and longevity across varied industries.

In metallurgy, they are extensively used for melting non-ferrous steels like light weight aluminum, copper, and zinc, as well as rare-earth elements such as gold and silver. Their resistance to thaw metal corrosion protects against contamination, ensuring pureness in spreading and alloy manufacturing. Shops benefit from their thermal shock resistance during rapid heating and cooling down cycles, lowering fracturing risks.

Chemical processing sectors utilize these crucibles for high-temperature responses entailing aggressive acids, antacid, and salts. They keep structural stability when taking care of corrosive reagents, making them appropriate for manufacturing specialized chemicals and stimulants.

Semiconductor manufacturing relies on their oxidation resistance for processes like silicon crystal growth and doping, where very little contamination is essential. The crucibles stand up to responsive gases and extreme warm in CVD and epitaxial development procedures, ensuring consistent efficiency.

In steel recycling, these crucibles successfully melt scrap steels, even those with harsh impurities, boosting recuperation prices while enduring repetitive thermal tension.

Glass and ceramic markets use them to thaw basic materials at high temperatures, where oxidation resistance stops degradation throughout long term heating system use. Their non-reactive nature preserves material quality in optical glass or sophisticated ceramic production.

Aerospace and vehicle sectors employ these crucibles for precision casting of high-performance elements, taking advantage of their capability to take care of superalloys and titanium.

Key advantages include expanded service life, reducing substitute costs, and power effectiveness because of superior thermal conductivity. Their robustness in rough problems ensures operational connection, making them an economical service for markets prioritizing toughness and efficiency. By preserving material pureness and resisting degradation, these crucibles improve performance and quality sought after applications.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible

What is a Silicon Carbide Graphite Crucible? A Silicon Carbide Graphite Crucible is a high-performance container made by combining silicon carbide (SiC) and graphite. This hybrid material enhances strength, thermal conductivity, and resistance to thermal shock, making it ideal for melting and holding metals, alloys, and other materials at extreme temperatures. The silicon carbide adds hardness and oxidation resistance, while graphite ensures excellent heat transfer and durability.

Why is this crucible highly corrosion-resistant? The silicon carbide in the crucible forms a protective layer that resists chemical reactions with acidic, alkaline, or molten metal environments. Its dense structure minimizes porosity, preventing corrosive substances from penetrating the surface. This makes it suitable for applications involving aggressive materials like aluminum, zinc, or copper alloys, as well as fluxes and salts used in metal processing.

How does it resist oxidation at high temperatures? Silicon carbide oxidizes at extreme temperatures to form a passive silica (SiO₂) layer on the surface, which acts as a barrier against further oxygen penetration. The graphite component is protected by this layer, preventing rapid degradation. This dual resistance allows the crucible to withstand temperatures up to 1650°C (3002°F) continuously and up to 1750°C (3182°F) intermittently without significant wear.

What industries or applications use this crucible? It is widely used in foundries, metallurgy, jewelry making, and laboratories for melting non-ferrous metals (e.g., gold, silver, aluminum), superalloys, and reactive materials. It’s also employed in recycling scrap metal, glass production, and high-temperature chemical processes where durability and thermal efficiency are critical.

How do I maintain it, and what is its lifespan? Avoid sudden temperature changes to prevent thermal shock. Clean residues after each use with appropriate tools (e.g., brushes) and store it in a dry environment. Lifespan depends on usage intensity—proper handling can extend it to hundreds of cycles. Signs of wear include surface cracks, thinning walls, or reduced heating efficiency. Replace the crucible if damage compromises structural integrity.

(High Corrosion Resistance Oxidation Resistance Silicon Carbide Graphite Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal

High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

Silicon Carbide Clay Crucible For Melting Copper

High Quality Best Induction Melting Molybdenum crucible

100-1000kg large capacity smelting furnace graphite crucibles silicon carbide crucible for melting meta