Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

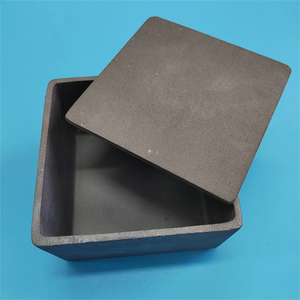

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide)

Specification of High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide

The High Purity 1 to 30Kg Graphite Crucible Mold, featuring a Single Ring design, is engineered for precision casting of silicon carbide and other high-temperature applications. Crafted from ultra-pure graphite with a carbon content exceeding 99.9%, this crucible ensures minimal contamination, making it ideal for processes requiring strict material integrity. Its robust construction supports weights ranging from 1kg to 30kg, accommodating diverse industrial needs. The crucible’s dimensions vary accordingly, with customizable inner diameters (50mm to 300mm), outer diameters (80mm to 400mm), and heights (100mm to 450mm) to suit specific furnace setups.

Designed to withstand extreme temperatures up to 3000°C in inert environments and 500°C in oxidizing conditions, this crucible excels in thermal stability. Its high thermal conductivity ensures rapid, uniform heat distribution, critical for consistent melting and casting results. The dense structure (1.75-1.85 g/cm³) enhances durability, reducing wear from abrasive materials like silicon carbide. The single ring reinforcement around the crucible’s exterior improves structural integrity, minimizing cracking under thermal stress and mechanical load.

Key specifications include low ash content (<0.2%) for purity retention, exceptional thermal shock resistance to prevent fractures during rapid temperature changes, and oxidation-resistant surfaces for prolonged lifespan. Applications span silicon carbide casting, metal alloy melting (gold, silver, aluminum), semiconductor processing, and laboratory experiments. Advantages include extended service life due to slow oxidation rates, energy efficiency from optimized heat transfer, and resistance to slag adhesion for easy maintenance. Customization options allow tailored dimensions, wall thickness, and surface treatments (e.g., anti-oxidation coatings) to meet specialized requirements. Handling recommendations include gradual preheating to avoid thermal shock and storage in dry conditions to prevent moisture absorption. This crucible is a reliable, cost-effective solution for industries prioritizing precision, durability, and performance in high-temperature environments. Its combination of purity, thermal resilience, and adaptable design makes it a superior choice for advanced metallurgical and material science applications.

(High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide)

Applications of High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide

High Purity 1 to 30kg Graphite Crucible Mold with a Single Ring design is engineered for precision and durability in high-temperature industrial applications, particularly in casting silicon carbide. Crafted from ultra-pure graphite (99.9% carbon content), these crucibles ensure minimal contamination, making them ideal for processes requiring strict material integrity. Their robust thermal conductivity (100-150 W/m·K) and resistance to extreme temperatures (up to 3000°C in inert environments) enable efficient heat distribution, reducing energy consumption and improving melting consistency. The single-ring structure enhances stability during handling and pouring, while the mold’s uniform density and fine-grained composition resist thermal shock, preventing cracks during rapid temperature shifts.

Primarily used in silicon carbide production, these crucibles withstand the aggressive chemical reactions and high heat involved in synthesizing and casting SiC crystals, crucial for semiconductors, LED lighting, and power electronics. They are also suitable for melting non-ferrous metals (gold, silver, copper) and alloys in foundries, labs, and jewelry manufacturing. Industries like aerospace, renewable energy, and advanced ceramics rely on their longevity and reliability for repeated use without performance degradation.

The graphite crucible’s machined precision ensures consistent wall thickness and smooth surfaces, reducing material adherence and simplifying post-process cleanup. Available in 1–30kg capacities, they cater to small-scale experiments and mid-volume production. Customizable dimensions and shapes are offered to meet specific furnace or process requirements.

Compared to ceramic or metal alternatives, these graphite molds provide superior thermal efficiency, faster cycle times, and extended service life, lowering replacement costs. Quality-tested for density, porosity, and mechanical strength, they comply with industrial standards for high-temperature applications.

In summary, the High Purity Graphite Single Ring Crucible is a critical tool for industries demanding precision, purity, and resilience in extreme conditions. Its versatility in handling silicon carbide and other high-melting-point materials makes it indispensable for advancing technology in electronics, metallurgy, and materials science.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide

**What is the purity level of your graphite crucible, and why does it matter?**

Our high-purity graphite crucibles boast a carbon content of 99.9% or higher, ensuring minimal impurities. This is critical for applications like silicon carbide casting, where contaminants can compromise material integrity, thermal stability, and final product quality. High purity also enhances resistance to oxidation and chemical erosion, extending the crucible’s lifespan.

**What temperature range can this graphite crucible withstand?**

The crucible operates effectively in temperatures up to 3000°C in inert or vacuum environments. However, in oxidizing atmospheres, we recommend limiting use to 600–800°C to prevent rapid oxidation. Its exceptional thermal conductivity ensures even heat distribution, making it ideal for high-temperature melting and casting processes.

**How do I choose the right crucible size (1–30 kg)?**

Select a capacity based on your production volume and furnace dimensions. Smaller crucibles (1–5 kg) suit lab-scale or precision casting, while larger models (10–30 kg) are designed for industrial batches. Ensure the crucible’s outer diameter and height align with your furnace’s chamber to avoid operational inefficiencies.

**What maintenance ensures a long lifespan for the crucible?**

Avoid sudden temperature changes to prevent thermal shock. Preheat the crucible gradually before use and allow it to cool naturally post-operation. Clean residues after each use with non-abrasive tools, and store it in a dry environment. With proper care, the crucible can last dozens of cycles, depending on operating conditions.

**Is this crucible compatible with materials other than silicon carbide?**

Yes, it’s suitable for melting non-ferrous metals (e.g., gold, aluminum) and alloys, as well as semiconductors and rare earth materials. However, avoid using it with iron, steel, or highly reactive substances unless in a controlled inert atmosphere. Always verify chemical compatibility to prevent corrosion or contamination.

(High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide)

REQUEST A QUOTE

RELATED PRODUCTS

Good Quality Silicon Carbide Graphite Crucible Silicon Carbide Crucible for Aluminum Melting Foundry

50 Kg Industrial Silicon Carbide Graphite Crucible For Smelting

Graphite crucible For Vacuum Deposition

Factory Silicon Carbide Melting Glass Graphite Crucible For Jewelry

Silicon Carbide Ceramic Crucible For Industrial Ceramic