Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

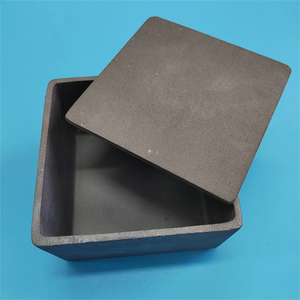

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(high quality aluminium crucible made of silicon carbide graphite)

Specification of high quality aluminium crucible made of silicon carbide graphite

This high-quality aluminum crucible combines silicon carbide and graphite for superior performance. The material mix ensures excellent heat resistance and durability. It handles temperatures up to 1600°C without cracking or warping. Thermal conductivity is high, allowing even heat distribution during metal melting. This reduces energy waste and improves process efficiency. The crucible resists chemical reactions with molten metals like aluminum, zinc, and alloys. This prevents contamination and extends service life. Its dense structure minimizes oxidation, maintaining purity in high-temperature environments.

Mechanical strength is a key feature. The crucible withstands physical stress during pouring, stirring, or handling. It resists abrasion from metal slag and frequent thermal cycling. The smooth inner surface prevents material sticking, simplifying cleanup. Design includes reinforced walls for added stability. Multiple sizes are available to fit standard and custom furnace setups. Common capacities range from 1 kg to 50 kg.

The crucible works with induction furnaces, gas-fired furnaces, and electric resistance systems. It suits foundries, labs, and recycling facilities. Proper preheating before first use is advised to remove moisture and prevent thermal shock. Regular inspection for cracks or erosion ensures safe operation. Avoid sudden temperature changes to maximize lifespan.

Storage recommendations include keeping the crucible in a dry, cool place away from direct moisture. Use tongs or lifting tools designed for high-temperature handling. Pair with appropriate flux coatings if required for specific alloys. Replacement intervals depend on usage intensity and material types processed. Consistent performance makes it a reliable choice for repeated melting tasks. Maintenance is minimal, reducing downtime in industrial settings. Compatibility with automated systems streamlines production workflows.

(high quality aluminium crucible made of silicon carbide graphite)

Applications of high quality aluminium crucible made of silicon carbide graphite

High-quality aluminium crucibles made of silicon carbide graphite are widely used in industries that require extreme heat resistance and durability. These crucibles handle high-temperature processes efficiently. They are ideal for melting, holding, or transferring metals like aluminum. Their material composition combines silicon carbide and graphite. This mix ensures strength while resisting wear from intense heat or chemical reactions.

These crucibles work well in foundries and metallurgical operations. They maintain stability at temperatures exceeding 1600°C. Traditional clay or ceramic crucibles often crack under rapid temperature changes. Silicon carbide graphite crucibles resist thermal shock. This makes them reliable for repeated heating and cooling cycles. Industries save costs by reducing replacements and downtime.

Laboratories use these crucibles for precision tasks. They are common in material testing or alloy development. Their non-reactive surface prevents contamination of samples. This ensures accurate results in experiments. The smooth interior allows easy removal of molten materials. Cleaning becomes simpler compared to porous alternatives.

Recycling aluminum relies heavily on these crucibles. They withstand prolonged exposure to molten metal without degrading. Scrap aluminum melts uniformly inside them. This improves the quality of recycled products. Manufacturers in aerospace and automotive sectors prefer these crucibles for producing high-performance components. Consistency in melting ensures alloys meet strict industry standards.

Handling these crucibles requires care. Users must avoid sudden impacts or uneven heating. Proper storage extends their lifespan. Workers should inspect them regularly for surface cracks or erosion. Small defects can grow under stress. Timely maintenance prevents accidents during high-heat operations.

The design of silicon carbide graphite crucibles supports energy efficiency. They conduct heat evenly. This reduces the time needed to reach target temperatures. Fuel or electricity consumption drops. Companies lower operational costs while boosting productivity.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of high quality aluminium crucible made of silicon carbide graphite

High-quality aluminum crucibles made of silicon carbide graphite are designed for demanding applications. Here are five common questions users ask.

What makes silicon carbide graphite suitable for crucibles? Silicon carbide graphite combines strength and heat resistance. The material handles extreme temperatures without cracking. It resists chemical reactions with molten metals. This ensures consistent performance over many uses.

What temperature range do these crucibles withstand? They operate effectively up to 1600°C. This suits melting aluminum and similar metals. Sudden temperature changes rarely damage them. Regular crucibles might fail under similar stress.

How long do these crucibles last compared to others? They outlast traditional ceramic or clay crucibles. Proper care extends their lifespan further. Rough handling or overheating shortens it. Users report fewer replacements over time.

How do I maintain a silicon carbide graphite crucible? Clean it after each use to remove residue. Avoid harsh tools that scratch the surface. Store it in a dry place to prevent moisture damage. Check for cracks before reheating.

Can these crucibles be used for metals other than aluminum? Yes. They work with copper, brass, and certain alloys. Avoid materials that react with graphite. Test compatibility if unsure. The crucible’s stability reduces contamination risks.

These answers address practical concerns for industrial or laboratory users. The focus remains on reliability and cost-effectiveness.

(high quality aluminium crucible made of silicon carbide graphite)

REQUEST A QUOTE

RELATED PRODUCTS

High Carbon Graphite Crucible, Sic Silicon Carbide Crucible for Melting Gold, Brass, Copper, Glass

High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

Good Quality Factory Sic Silicon Carbide Sagger Graphite Crucible for Melting

Silicon carbide pin semiconductor device precision parts corrosion resistance

Silicon Carbide Graphite Crucible for Induction Furnaces