Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

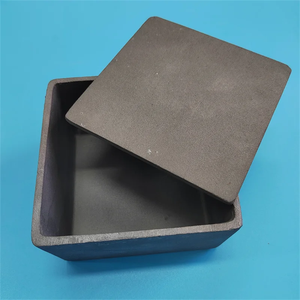

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High Quality Best Induction Melting Molybdenum crucible)

Specification of High Quality Best Induction Melting Molybdenum crucible

High-quality induction melting molybdenum crucibles are built for requiring high-temperature applications. These crucibles handle severe conditions in commercial and laboratory settings. The material is pure molybdenum with a minimum purity of 99.95%. This ensures resistance to thermal tension and chain reaction. The thickness varies from 10.2 g/cm six to 10.4 g/cm ³. This high density improves durability and extends service life under duplicated home heating cycles. The melting point is 2623 ° C. This allows steady efficiency in settings exceeding 2000 ° C. The thermal conductivity is 138 W/m · K. This promotes effective warm circulation and minimizes energy waste throughout melting processes.

The production procedure makes use of sophisticated powder metallurgy methods. High-pressure isostatic pressing types the crucible structure. This approach gets rid of interior problems and improves mechanical toughness. Precision machining develops smooth internal surface areas. This reduces product adhesion and simplifies cleansing. The crucibles undertake rigorous quality checks. Measurements are accurate to ± 0.5 mm. Wall surface thickness consistency is maintained within ± 0.2 mm.

These crucibles work well with induction heating systems. They are compatible with steels like platinum, titanium, and uncommon planet alloys. The non-reactive nature of molybdenum protects against contamination of melted products. This is critical for applications in semiconductor production and aerospace element manufacturing.

The layout includes a tapered base. This allows total putting of molten products. The thick wall surfaces stand up to contortion under fast temperature changes. Customers take advantage of lowered downtime and maintenance prices.

Standard dimensions vary from 50 ml to 5000 ml ability. Custom shapes and sizes are offered. Surface area therapies like polishing or coating can be added. These choices enhance efficiency for specific industrial demands.

Molybdenum crucibles surpass graphite or ceramic options. They last longer in severe heat. They take care of thermal biking without breaking. Their low oxidation price at high temperatures decreases product loss.

Appropriate handling expands crucible life. Stay clear of mechanical influence throughout installation. Preheat gradually before very first use. Shop in completely dry conditions to prevent oxidation. Clean deposits promptly after cooling down.

(High Quality Best Induction Melting Molybdenum crucible)

Applications of High Quality Best Induction Melting Molybdenum crucible

High-grade induction melting molybdenum crucibles play a key duty in industries requiring exact high-temperature procedures. These crucibles manage severe warmth well. They operate in settings over 2000 ° C. This makes them optimal for thawing steels like platinum, titanium, and rare planet alloys. Their strength at high temperatures prevents splits or warping. This makes sure consistent performance over numerous uses.

Industrial steel production depends on these crucibles. Factories utilize them to create high-purity alloys. The crucibles resist chain reactions with molten steels. This maintains the final product free from contamination. Molybdenum’s stability under heat enables consistent melting. This is essential for aerospace parts and clinical tools requiring precise product properties.

Laboratories make use of molybdenum crucibles for research study and small experiments. Researchers test brand-new materials or improve melting techniques. The crucibles’ durability supports duplicated home heating and cooling down cycles. This decreases downtime from equipment substitute. Their thermal effectiveness speeds up experiments. This assists scientists gather data faster.

Electronics producing gain from these crucibles. They thaw materials for semiconductors and progressed coverings. Exact temperature level control ensures elements meet rigorous top quality criteria. Molybdenum crucibles handle reactive substances like silicon or gallium. This stops pollutants in delicate electronic parts.

The precious jewelry market uses these crucibles for rare-earth elements. Gold and silver need tidy melting problems. Molybdenum crucibles avoid introducing foreign bits. Jewelers accomplish smoother casts and finer details. This boosts the final product’s look and value.

Energy market applications include refining products for batteries and solar cells. High-purity steels are essential for effective energy storage. Molybdenum crucibles enable trustworthy production of these materials. Their heat resistance sustains continuous procedure in massive setups.

Sturdiness lowers lasting prices. These crucibles outlive options like graphite or ceramic. Less replacements mean much less waste and decreased downtime. This is very important for industries prioritizing performance and sustainability.

Taking care of these crucibles requires care. Correct preheating and cooling down expand their lifespan. Operators needs to avoid sudden temperature modifications. Right maintenance guarantees consistent outcomes and security.

Compatibility with induction heating systems contributes to their convenience. They integrate efficiently right into existing systems. This makes upgrades or process changes less complex for manufacturers.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Best Induction Melting Molybdenum crucible

What is a molybdenum crucible? A molybdenum crucible is a container made from molybdenum metal. It is used in high-temperature industrial processes like melting metals. Molybdenum has a high melting point and resists corrosion. This makes it ideal for handling extreme heat and reactive materials.

Why choose a molybdenum crucible for induction melting? Molybdenum conducts electricity efficiently. Induction melting relies on electromagnetic fields to generate heat. The crucible must handle rapid temperature changes without cracking. Molybdenum’s strength and thermal stability make it reliable. It lasts longer than other materials under similar conditions.

What temperatures can a molybdenum crucible withstand? Molybdenum crucibles operate effectively up to 2600°C. They maintain structural integrity even near their melting point of 2623°C. This exceeds the limits of most metals. It ensures consistent performance in demanding applications like aerospace or advanced alloy production.

How do I maintain a molybdenum crucible? Avoid exposing it to oxygen at high temperatures. Oxidation weakens the material over time. Use inert gases like argon during heating. Clean the crucible after each use to remove residue. Handle it carefully to prevent physical damage. Proper care extends its lifespan significantly.

Are there safety precautions for using molybdenum crucibles? Wear protective gear when handling hot crucibles. Ensure the workspace is well-ventilated to avoid inhaling fumes. Do not expose the crucible to water or moisture while hot. Thermal shock can cause cracks. Follow manufacturer guidelines for heating and cooling rates.

(High Quality Best Induction Melting Molybdenum crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Melting non-ferrous metal using graphite silicon carbide crucible 5kgs to 500kgs

KERUI High Purity 5kg 500 Kg Silicon Carbide Crucible Sic Casting Graphite Crucibles and Tubes for Melting Cast Iron

Small Casting Gold Pure 500kg Large Glass Graphite 50kg Aluminum Melting Copper Silicon Iron Carbide Graphene Crucible

Silicon carbide graphite crucible for all kinds of metal casting melting

Large Smelting Furnace Silicon Sizes Melting Carbide Crucible Steel Clay Cast Sic 100kg Iron Graphite Crucibles for