Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

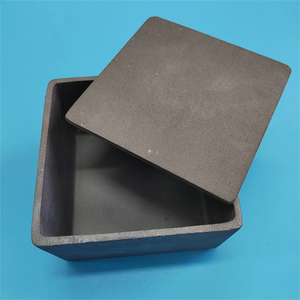

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High temperature metal melting graphite crucible silicon carbide graphite crucible for gold iron aluminum copper melting)

Specification of High temperature metal melting graphite crucible silicon carbide graphite crucible for gold iron aluminum copper melting

This graphite crucible handles severe heat for melting steels. It’s made from silicon carbide graphite. This product is difficult. It lasts long under severe problems. You require crucibles that survive duplicated use. This one does. It resists thermal shock very well. Sudden temperature adjustments won’t break it easily. This crucible withstands temperatures over 1600 ° C. That’s warm sufficient for gold, silver, copper, iron, light weight aluminum, and brass. It functions excellent in heaters, kilns, and factories. The graphite core heats up fast. It moves warmth efficiently. You save energy. Thawing occurs quicker. The silicon carbide coating adds extra toughness. It combats chemical deterioration. Molten steel does not stick as much. Cleansing is less complicated. The crucible form is basic. It fits most common furnace arrangements. Dimensions differ. You locate the right one for your melt volume. The wall surfaces are thick. They supply good insulation. Warmth remains within. Temperature level control is better. Metal remains molten longer. This crucible deals with hefty lots. It does not flaw conveniently. You obtain constant performance thaw after thaw. It’s built for requiring work. Utilize it for casting jewelry, making alloys, or recycling scrap metal. Always preheat brand-new crucibles gradually. Comply with safety and security rules. Use protective gear. Manage molten steel very carefully. Store crucibles dry. Prevent wetness. Check for splits before each use. Change damaged crucibles right away. Excellent upkeep prolongs crucible life. This device is essential for serious metal melting.

(High temperature metal melting graphite crucible silicon carbide graphite crucible for gold iron aluminum copper melting)

Applications of High temperature metal melting graphite crucible silicon carbide graphite crucible for gold iron aluminum copper melting

Heat metal melting graphite crucibles function well for several applications. Jewelers utilize them for thawing gold and silver. These crucibles take care of the heat without polluting precious metals. Factories rely on them for thawing copper and copper alloys. Copper needs heats. Graphite crucibles provide this accurately. Light weight aluminum factories utilize them too. Recyclers melt scrap aluminum in these crucibles. The material holds up against aluminum’s corrosive nature. Melting iron calls for even greater warmth. Silicon carbide graphite crucibles manage this severe need. They are harder than regular graphite. Iron shops utilize them for casting components.

Silicon carbide graphite crucibles use details advantages. They stand up to thermal shock quite possibly. Quick temperature level changes will not split them quickly. This implies longer life span. They endure the greatest heater temperatures. This is crucial for metals like iron. The material is chemically secure. It doesn’t react with the majority of liquified metals. This maintains your melt pure. Silicon carbide graphite crucibles are also extremely solid. They withstand wear and disintegration better. You obtain more thaws from each crucible. This conserves money in time.

These crucibles are essential tools. Gold melters require purity. Copper and aluminum melters require resilience. Iron melters require extreme heat resistance. Silicon carbide graphite crucibles satisfy these demands effectively. They perform consistently under hard problems. Selecting the best crucible matters for your operation. Think about the steel kind and melting temperature. Consider your heater conditions. Appropriate crucible selection ensures reliable melting. It lowers downtime and substitute costs.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High temperature metal melting graphite crucible silicon carbide graphite crucible for gold iron aluminum copper melting

Graphite Crucibles: Your Metal Melting Questions Answered

What exactly are graphite crucibles made from?

These crucibles mix graphite powder with silicon carbide. Graphite handles extreme heat. Silicon carbide adds strength. Together they resist cracking better than pure graphite. This mix works for melting many metals.

How hot can these crucibles get?

They handle very high temperatures safely. Typically, they withstand heats between 1500°C and 1800°C. This range covers melting gold, silver, copper, aluminum, and even iron. Always check your specific crucible’s rating first.

Will one crucible last a long time?

Lifespan depends heavily on use. Melting different metals affects it. How hot you run matters. How carefully you handle it counts. Using the right tools helps. Generally, silicon carbide graphite crucibles last longer than pure graphite ones. Expect dozens of melts with proper care.

Do I need to prepare a new crucible?

Yes, preheating is essential. Never skip this step. Slowly heat the empty crucible to around 500°F (260°C). Hold it there for 30 minutes. This drives out moisture. Sudden high heat cracks crucibles with moisture inside. It prevents dangerous steam explosions.

What safety steps are critical?

Always wear protective gear. Use heat-resistant gloves and face shields. Work in a well-ventilated area. Fumes from melting metals are harmful. Never overfill the crucible. Keep molten metal levels below the top rim. Use proper tongs designed for crucibles. Avoid thermal shock – don’t expose a hot crucible to cold surfaces or liquids.

(High temperature metal melting graphite crucible silicon carbide graphite crucible for gold iron aluminum copper melting)

REQUEST A QUOTE

RELATED PRODUCTS

Customized SIC Silicon Carbide Ceramic Crucible

silicon carbide graphite crucible for aluminium meltin

SIC Silicon Carbide Tubes/bush/sleeve

Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting

High Purity Silicon Carbide Graphite Crucible 50kg for Melting Aluminum Copper