Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

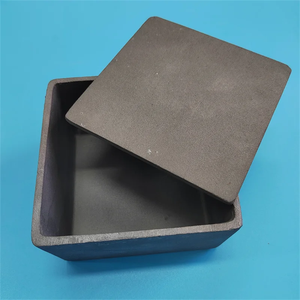

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal)

Specification of High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal

This crucible is created for melting metals at high temperatures. It integrates graphite and silicon carbide for stamina and heat resistance. The product mix ensures it deals with extreme problems without fracturing or degrading. It works in atmospheres approximately 1600 ° C (2912 ° F). This makes it ideal for thawing light weight aluminum, copper, gold, and other metals.

The graphite material improves thermal conductivity. Heat spreads equally throughout the crucible wall surfaces. This decreases locations and prevents irregular melting. Silicon carbide adds solidity and longevity. It stands up to wear from duplicated usage and abrasive products. The mix extends the crucible’s lifespan contrasted to conventional clay or ceramic options.

Its structure withstands thermal shock. Rapid temperature changes won’t create fractures. This is essential when moving the crucible between home heating and cooling cycles. The smooth internal surface minimizes metal sticking. Cleaning is less complicated, and product waste is minimized.

The crucible can be found in several sizes. Usual abilities range from 1kg to 50kg. Custom dimensions are offered for commercial setups. Wall surfaces are enlarged to deal with prolonged direct exposure to thaw steel. A reinforced edge adds stability during pouring.

Chemical resistance is another key function. It holds up against acidic or alkaline slag developed throughout melting. Oxidation is reduced even in oxygen-rich environments. This maintains the crucible from damaging down gradually.

Applications consist of factories, precious jewelry workshops, and oral laboratories. It collaborates with electric heaters, gas-fired heating systems, and induction melters. Customers report regular efficiency throughout numerous cycles. Maintenance is simple– examine for splits and tidy after each usage.

The product ships with a protective covering to avoid damage during transportation. Storage space suggestions consist of keeping it completely dry and away from straight dampness. Managing tools like tongs or lifts must match the crucible’s size to prevent tipping.

(High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal)

Applications of High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal

High-temperature immune graphite silicon carbide crucibles are important devices in metal melting processes. These crucibles integrate graphite and silicon carbide, producing a material that deals with extreme warmth and extreme conditions. They work well in temperatures as much as 1800 ° C, making them appropriate for thawing metals like gold, silver, copper, and light weight aluminum. The mix of graphite and silicon carbide improves thermal conductivity, making sure also warmth distribution. This reduces energy waste and speeds up melting.

The crucibles withstand thermal shock, preventing fractures when temperatures change rapidly. This longevity expands their life expectancy, decreasing substitute prices. They also deal with chemical corrosion from molten metals and slag, maintaining architectural stability in time. These features make them reliable for duplicated usage popular atmospheres.

Metalworkers and jewelry experts usually utilize these crucibles for small-scale procedures. They melt precious metals efficiently, making sure consistent quality in casting or alloying. Industrial foundries rely on them for large-volume production of steel, iron, and non-ferrous metals. The crucibles’ strength sustains hefty loads without damaging, even under extreme warm.

Aerospace and automobile industries take advantage of these crucibles when creating high-performance metal components. They thaw specialized alloys needing specific temperature level control. The material’s security protects against contamination, making sure pure final products. This is essential for parts requiring strict mechanical residential or commercial properties.

These crucibles match electric and gas-fired heaters, using versatility across various configurations. Their light-weight layout streamlines dealing with contrasted to conventional clay-graphite alternatives. Individuals save time and lower physical stress throughout loading and putting.

Cost-effectiveness is another benefit. Long life span and marginal maintenance reduced operational expenditures. Businesses attain higher performance with less interruptions for crucible adjustments. Constant efficiency also reduces product waste, boosting overall efficiency.

High-temperature graphite silicon carbide crucibles fulfill the demands of modern metal melting. Their warmth resistance, sturdiness, and versatility make them a practical option for both tiny workshops and big commercial centers. They sustain diverse applications while making certain reputable outcomes under extreme conditions.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal

What is a high-temperature resistant graphite silicon carbide crucible? It is a container for melting metals. It combines graphite and silicon carbide. These materials handle extreme heat well. They resist thermal shock and corrosion. The crucible works in furnaces and foundries. It melts metals like gold, silver, aluminum, and copper. Traditional clay or ceramic crucibles break easier. This type lasts longer.

Why pick a graphite silicon carbide crucible for metal melting? It handles temperatures over 1600°C. This suits most metal melting jobs. It heats up fast. This saves energy. It cools down without cracking. Other crucibles might fail under sudden temperature changes. This one stays durable. It also resists chemical reactions with molten metals. You avoid contamination. Over time, it costs less because it doesn’t need replacing often.

What’s the maximum temperature this crucible can take? Most handle 1600°C to 1800°C. Specific limits depend on the brand. Check the manufacturer’s guidelines. Going over the limit risks damage. The crucible might warp or crack. Exact numbers vary with size and design. Always stay within recommended ranges for safety.

How long does a graphite silicon carbide crucible last? It depends on use. Frequent high-temperature melting shortens life. Harsh metals like iron cause more wear. Proper care extends lifespan. Avoid overheating. Don’t switch temperatures too fast. Clean after each use. Check for cracks or thinning. With good maintenance, it lasts months or years.

Any safety tips for using these crucibles? Wear heat-resistant gloves and goggles. Inspect the crucible before heating. Cracks or damage can cause leaks. Heat it slowly to prevent shock. Never exceed the maximum temperature. Let it cool fully before handling or cleaning. Store it somewhere dry. Moisture weakens the material. Follow these steps to avoid accidents.

(High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal)

REQUEST A QUOTE

RELATED PRODUCTS

high quality refractory silicon carbide foundry crucible

Hot Sic Graphite Crucible Graphite Foundry Silicon Carbide Graphite Crucible for Iron Metal Melting

SiC Silicon Carbide Puffco Peak Ceramic Volatilization Heating Crucible with lid

Customized refractory Foundry Silicon carbide sagger SiC graphite crucible for aluminum smelting

Isotatic Pressing Sintered Silicon Carbide SiC Crucible