Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

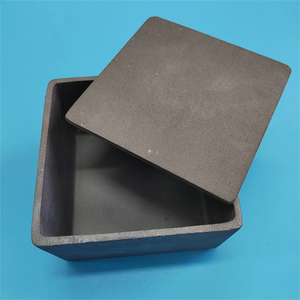

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding)

Specification of High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

High Put On Resistance Silicon Carbide Crucible Manufacturing facility uses costs ceramic crucibles and custom refractory elements engineered for severe commercial applications. Our silicon carbide (SiC) crucibles are made utilizing sophisticated sintering methods, making certain premium thermal, mechanical, and chemical efficiency. These crucibles are ideal for shops, metal smelting, laboratories, and high-temperature processing industries needing resilience under rough problems.

** Material Requirements **: The crucibles are crafted from high-purity silicon carbide (≥ 98% SiC), enhanced with binding agents to improve structural stability. This make-up supplies phenomenal wear resistance, decreasing erosion from rough molten steels and slag. The product’s intrinsic firmness (Mohs 9.5) ensures extended service life also under continuous mechanical anxiety.

** Thermal Properties **: With an optimum operating temperature level of 1650 ° C, our SiC crucibles show outstanding thermal shock resistance, swiftly adjusting to temperature level variations without splitting. High thermal conductivity makes sure efficient heat circulation, minimizing energy consumption throughout steel melting.

** Personalization **: We provide multi-size crucibles customized to customer requirements, ranging from small lab versions (50 ml) to huge industrial layouts (500+ kg capacity). Personalized forms, wall densities, and lip arrangements are available to suit certain furnace arrangements or automated systems.

** Refractory Welding Providers **: Beyond crucibles, we make and fix custom-made ceramic parts using specialized refractory welding techniques. Our know-how guarantees smooth joints in intricate SiC parts, preserving thermal stability and mechanical stamina in high-stress atmospheres.

** Applications **: Ideal for melting non-ferrous steels (aluminum, copper), rare-earth elements (gold, silver), and ferrous alloys. Resistant to acidic/alkaline slags, these crucibles are also utilized in chemical handling and aerospace markets.

** Quality control **: Each item undergoes extensive testing, including dimensional accuracy checks, thermal biking examinations, and porosity analyses. Our factory makes use of ISO-certified procedures, guaranteeing uniformity and reliability.

** Advantages **: Clients take advantage of decreased downtime as a result of extensive crucible life-span, price financial savings from energy-efficient performance, and customized solutions for particular niche applications.

Partner with our factory for high-performance SiC crucibles and refractory options that focus on accuracy, durability, and flexibility. Call us to go over custom measurements or technical requirements– your optimal ceramic element is just an appointment away.

(High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding)

Applications of High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

High wear resistance silicon carbide crucibles are necessary parts in industries needing sturdy, high-performance materials for severe thermal and mechanical problems. Manufactured by a specialized manufacturing facility with proficiency in innovative ceramics, these crucibles are engineered to withstand intense heat, chemical deterioration, and abrasive environments, making them suitable for applications in steel smelting, chemical processing, semiconductor production, and refractory welding. Their remarkable thermal conductivity, resistance to thermal shock, and durability reduce downtime and functional prices.

A vital benefit of partnering with a silicon carbide crucible manufacturing facility is the accessibility of multi-size personalized solutions. Customers can ask for crucibles tailored to details measurements, forms, or abilities, making certain compatibility with distinct industrial equipment or processes. This versatility is vital for industries like aerospace, renewable resource, and accuracy design, where common sizes might not meet technical demands. Custom-made ceramic components, consisting of nozzles, liners, and welding elements, are additionally created to enhance efficiency in refractory welding applications, where heat administration and use resistance are critical.

In refractory welding, silicon carbide crucibles and ceramic parts play an essential role in preserving architectural integrity during high-temperature operations. They are made use of to thaw and put steels or alloys for welding repair work in furnaces, kilns, and reactors, where standard products stop working under extreme conditions. Their non-reactive nature makes sure purity in procedures involving molten metals or aggressive chemicals. Additionally, these crucibles are used in producing advanced porcelains, where specific temperature control and contamination-free environments are necessary.

The manufacturing facility’s dedication to high quality includes extensive screening for thickness, hardness, and thermal stability, making certain each item meets international requirements. By providing scalable manufacturing and customized solutions, the manufacturing facility sustains industries varying from hefty production to modern electronics. Whether for massive industrial operations or specialized refractory welding tasks, high wear resistance silicon carbide crucibles and customized ceramic components supply unrivaled reliability, efficiency, and cost-effectiveness, strengthening their function as crucial components in modern manufacturing and product processing.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

What is the advantage of using silicon carbide crucibles from your factory? Our high-wear resistance silicon carbide crucibles are engineered for extreme durability and thermal shock resistance. They withstand temperatures up to 1600°C, ideal for melting metals, alloys, and refractory materials. The unique composition ensures minimal erosion, reducing contamination risks and extending service life. Customizable sizes and shapes cater to industrial furnaces, labs, and specialized applications, ensuring precise performance for diverse thermal processes.

How does the multi-size custom service work? We offer tailored sizing for crucibles and ceramic parts based on client specifications. Provide your dimensions, capacity, or design sketches, and our team uses advanced molding and sintering techniques to create precision components. Customization covers diameter, height, wall thickness, and unique features like spouts or handles. This flexibility ensures compatibility with your equipment and operational requirements.

What industries benefit from your ceramic refractory products? Our silicon carbide crucibles and ceramic parts serve metallurgy, foundries, glass manufacturing, aerospace, and chemical processing. They’re also used in welding applications requiring high thermal stability. Industries relying on high-temperature melting, slag resistance, or prolonged heat exposure benefit from our products’ reliability and wear resistance.

How do you ensure quality in high-wear resistance crucibles? We use premium silicon carbide raw materials and strict ISO-certified manufacturing processes. Each crucible undergoes rigorous testing for density, thermal conductivity, and mechanical strength. Our advanced sintering technology enhances structural integrity, ensuring uniform heat distribution and resistance to cracking. Quality checks at every production stage guarantee compliance with industrial standards.

What is the typical lead time for custom orders? Standard products ship within 5–7 days. Custom orders require 2–4 weeks, depending on design complexity and quantity. We prioritize communication to align timelines with urgent needs. Bulk orders may qualify for expedited processing—contact our team for tailored solutions.

Why choose your factory for refractory welding components? Our expertise in silicon carbide ceramics ensures components withstand extreme abrasion, corrosion, and thermal stress. We combine material science with precision engineering to deliver welding parts that enhance process efficiency and equipment longevity. From crucibles to custom ceramic fixtures, we provide solutions optimized for high-wear, high-temperature environments.

(High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding)

REQUEST A QUOTE

RELATED PRODUCTS

SIC SSIC silicon carbide ceramic crucible

China small Melting Metal Silicon Carbide Graphite Crucible for Furnace Graphite Crucible

Ceramic Crucible Silicon Carbide Ceramic Crucible SIC for Heating Volatilation

Customized refractory Foundry Silicon carbide sagger SiC graphite crucible for aluminum smelting

1kg 2kg 6kg 8kg 10kg clay silicon carbide graphite crucible in stock for iron steel aluminum copper gold