Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

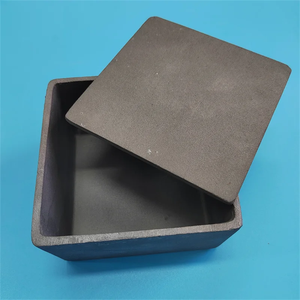

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(KERUI RBSIC / SISIC High Resistant SiC Silicon Carbide Pipe/Tube for High Temperature Furnace Tube)

Specification of KERUI RBSIC / SISIC High Resistant SiC Silicon Carbide Pipe/Tube for High Temperature Furnace Tube

The KERUI RBSIC/SISIC High Resistant SiC Silicon Carbide Pipe/Tube is created for high-temperature furnace applications. It is made from premium silicon carbide, ensuring excellent thermal stability and resistance to extreme warm. The product keeps architectural honesty in temperature levels up to 1650 ° C. This makes it suitable for commercial heating systems, kilns, and reactors requiring prolonged direct exposure to extreme warmth.

The pipe/tube includes high thermal conductivity, enabling efficient warmth transfer across systems. Its low thermal growth lessens contortion threats throughout rapid temperature changes. This decreases downtime and upkeep costs. The item also stands up to thermal shock, making it dependable in settings with unexpected home heating or cooling cycles.

Deterioration resistance is an essential advantage. The silicon carbide composition holds up against acids, antacid, and oxidizing agents. This guarantees durability in chemical handling, metallurgy, and semiconductor production. The material’s non-reactive nature avoids contamination, essential for high-purity applications.

Two qualities are available: RBSIC (reaction-bonded) and SISIC (sintered). RBSIC provides enhanced mechanical strength and cost-effectiveness for basic high-temperature uses. SISIC supplies greater pureness and density, suitable for advanced applications requiring exceptional wear resistance. Both qualities work with inert and destructive ambiences.

Criterion dimensions include internal diameters from 20mm to 300mm and lengths as much as 3000mm. Customized dimensions are offered. The pipe/tube’s smooth surface decreases rubbing, boosting liquid or gas circulation efficiency. It incorporates conveniently with existing heater configurations making use of common flange or threaded links.

Mechanical homes consist of high firmness (Mohs scale 9.5) and remarkable abrasion resistance. This expands life span in abrasive settings. The item’s load-bearing ability supports heavy industrial operations without architectural failing.

Setup is simple because of exact engineering. Upkeep requirements are very little, thanks to the product’s chemical inertness and thermal resilience. This ensures lasting performance with minimized operational disruptions.

Compliance with worldwide criteria like ISO 9001 and ASTM certifications warranties high quality. The product undertakes extensive screening for density, porosity, and thermal shock resistance. Each device is evaluated to meet industry-specific demands.

(KERUI RBSIC / SISIC High Resistant SiC Silicon Carbide Pipe/Tube for High Temperature Furnace Tube)

Applications of KERUI RBSIC / SISIC High Resistant SiC Silicon Carbide Pipe/Tube for High Temperature Furnace Tube

The KERUI RBSIC/SISIC High Resistant SiC Silicon Carbide Pipe/Tube is developed for high-temperature furnace applications. It manages extreme warm up to 1650 ° C. This makes it appropriate for markets needing reliable efficiency under extreme conditions. The material withstands thermal shock. It maintains strength even during quick temperature level modifications. This reduces cracking threats. The pipe/tube operates in oxidizing or harsh environments. It stays secure in settings with acids, antacid, or liquified steels.

These SiC pipelines are used in metallurgical heating systems. They transport liquified steels or alloys. They manage high warmth without weakening. Ceramic manufacturing uses them for sintering kilns. They make sure also heat circulation. This boosts product quality. Semiconductor production counts on them for crystal development furnaces. They give tidy, contamination-free heating. Chemical handling plants utilize the tubes in reactors. They stand up to aggressive gases or fluids.

The KERUI SiC pipelines have high thermal conductivity. This accelerates heating cycles. Power intake decreases. Their low thermal expansion avoids bending. This expands service life. The product withstands abrasion from particles in gas circulations. Upkeep costs remain low. Setup is basic. The pipelines are available in customized dimensions. They fit existing heating system setups.

These tubes are ideal for warmth therapy heaters. They take care of annealing, quenching, or solidifying processes. They carry out in glass manufacturing. They sustain creating or annealing glass items. The non-reactive surface prevents sticking. This guarantees smooth procedure.

The KERUI RBSIC/SISIC pipes are constructed for resilience. They last longer than conventional materials like alumina or metal alloys. They minimize downtime from replacements. Their lightweight layout eases handling. This reduces labor costs. They run successfully in continual commercial processes.

This item meets demands for high-temperature resistance. It supplies dependability in vital applications. It sustains markets going for productivity and price control.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of KERUI RBSIC / SISIC High Resistant SiC Silicon Carbide Pipe/Tube for High Temperature Furnace Tube

The KERUI RBSIC/SISIC High Resistant SiC Silicon Carbide Pipe/Tube is designed for extreme heat environments like industrial furnaces. Below are answers to common questions about this product.

What makes this silicon carbide pipe different from regular furnace tubes?

This pipe is made using reaction-bonded or sintered silicon carbide. These methods create a material with higher heat resistance. Regular tubes often fail under extreme temperatures. This product withstands temperatures up to 1650°C.

How long does it last in high-temperature applications?

The lifespan depends on operating conditions. It resists thermal shock, oxidation, and chemical corrosion. These features reduce wear from frequent heating cycles. Users report consistent performance for years without cracks or deformation.

Can it handle corrosive gases or chemicals?

Yes. Silicon carbide has natural resistance to acids, alkalis, and molten metals. This makes the pipe suitable for furnaces processing metals, ceramics, or semiconductors. It performs better than metals or ceramics in harsh chemical environments.

What industries use this product?

Industries needing high-temperature processing rely on these pipes. Examples include steelmaking, glass manufacturing, and aerospace. They work in sintering furnaces, heat treatment systems, and semiconductor production.

Is installation or maintenance complicated?

Installation follows standard procedures for furnace components. The material’s strength allows easy handling without special tools. Maintenance is minimal. Regular inspections check for surface wear or buildup. Cleaning involves basic methods like air blasting or non-abrasive wiping.

(KERUI RBSIC / SISIC High Resistant SiC Silicon Carbide Pipe/Tube for High Temperature Furnace Tube)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Silicon Carbide Graphite Crucible 50kg for Melting Aluminum Copper

High Quality Refractory Sagger SISIC RBSIC Silicon Carbide Graphite Crucible For Smelting

Flake Graphite Powder Black Powder High Carbon Low Sulfur Earthy Graphene Oxide Silicon Carbide Crucible

QIYUAN High Purity 5kg 500 Kg Silicon Carbide Crucible Sic Casting Graphite Crucibles Tubes Refractory Type Melting Cast Iron

Polished Graphite Crucible with High-Pure Quartz Isostatic Silicon Carbide Neck Cast Clay for Gold Smelting Refractory Material