Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

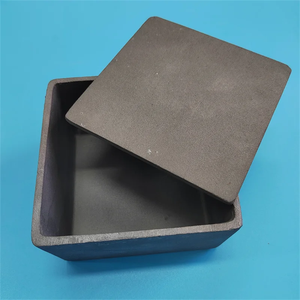

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Polished Graphite Crucibles with Necks Cast Clay Silicon Carbide for Gold Smelting High Quality Graphite Electrodes)

Specification of Polished Graphite Crucibles with Necks Cast Clay Silicon Carbide for Gold Smelting High Quality Graphite Electrodes

Polished graphite crucibles with necks cast from clay silicon carbide are made for gold smelting. These crucibles handle extreme warm and harsh problems. They combine graphite and silicon carbide for better performance. The product mix guarantees high thermal shock resistance. This makes them last longer under quick temperature level modifications. The crucibles function well in melting gold and various other precious metals.

The necks on these crucibles improve managing and pouring. The layout lowers spills and waste. The polished surface protects against steel sticking. This makes cleaning less complicated. The smooth coating likewise assists warm spread evenly. This maintains temperature levels steady during smelting.

Silicon carbide includes stamina and deterioration resistance. The clay spreading technique develops a thick framework. This framework stands up to splits and wear. The crucibles endure temperatures over 1600 ° C. They suit furnaces and induction heating systems.

Top quality graphite electrodes feature these crucibles. The electrodes perform electricity successfully. They decrease power loss during smelting. The graphite withstands oxidation at high warm. This maintains the electrodes from breaking down rapidly.

These crucibles fit gold smelting in jewelry making, labs, and small factories. They deal with duplicated home heating and cooling down cycles. Individuals save money and time with less replacement. Maintenance is straightforward. Clean the crucible after each usage. Shop it in a dry place. Look for fractures or damage consistently.

The dimension options match various smelting requirements. Little crucibles benefit specific jobs. Bigger ones manage bulk melting. All sizes keep the exact same quality criteria. The item satisfies commercial demands for security and performance.

Gold smelting needs trustworthy tools. These crucibles make certain regular outcomes. Their durability makes them a sensible selection. The mix of products and design addresses usual smelting obstacles. Customers focus on their job without tools issues.

The electrodes and crucibles interact efficiently. This configuration improves melting rate and pureness. Pollutants remain low due to the inert nature of graphite. The end product meets high pureness standards.

This item matches experts and newbies. Easy dealing with lowers the finding out curve. Efficiency remains reliable over time. Purchasing these crucibles sustains lasting smelting procedures.

(Polished Graphite Crucibles with Necks Cast Clay Silicon Carbide for Gold Smelting High Quality Graphite Electrodes)

Applications of Polished Graphite Crucibles with Necks Cast Clay Silicon Carbide for Gold Smelting High Quality Graphite Electrodes

Refined graphite crucibles with necks cast clay silicon carbide serve crucial functions in gold smelting. These crucibles manage severe heat. They function well in melting rare-earth elements like gold. The mix of graphite and silicon carbide enhances sturdiness. This mix stands up to thermal shock. It stops fractures throughout rapid temperature changes. The polished surface area lowers product sticking. This makes cleaning simpler after each usage. The neck layout improves safety. It allows controlled pouring of liquified gold. Spills and waste decrease.

Top quality graphite electrodes pair with these crucibles. Graphite electrodes perform electrical power effectively. They move warm equally in smelting heating systems. This accelerates melting. It additionally cuts power expenses. Steady performance matters in continual procedures. Graphite electrodes last much longer than alternatives. They hold up against deterioration from molten steels. Upkeep requires drop. Production remains consistent.

Gold smelting needs precise temperature control. These crucibles preserve stable warmth distribution. Impurities separate much better from gold. Final product pureness rises. The process ends up being more trustworthy. Small-scale and industrial setups benefit. Jewelers and refineries utilize them widely. Silicon carbide adds strength. It stops crucibles from contorting under stress and anxiety. Repetitive home heating cycles cause less wear. Substitute prices fall over time.

Safety and security boosts with the secure neck structure. Employees take care of liquified gold with decreased risk. Sprinkling cases decline. The layout suits hand-operated and automatic systems. Compatibility with different heater types adds adaptability. Users save time changing tools.

These crucibles help various other steels as well. Silver, platinum, and alloys melt efficiently. Flexibility raises their value. Top notch graphite electrodes sustain numerous applications. Their reduced resistance keeps power usage effective. Melting rates remain high. With each other, these devices optimize smelting process. They fulfill needs for top quality and efficiency. Users concentrate on result without equipment issues. Long-lasting cost savings issue for businesses. Performance dependability constructs count on results.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Polished Graphite Crucibles with Necks Cast Clay Silicon Carbide for Gold Smelting High Quality Graphite Electrodes

What makes these graphite crucibles suitable for gold smelting?

These crucibles use cast clay silicon carbide. This material handles extreme heat. It resists chemical corrosion. Gold smelting needs high temperatures. The crucible stays stable. It melts gold safely. The polished surface prevents impurities. This keeps the gold pure.

How does the neck design improve performance?

The neck makes pouring easier. It reduces spills. Handling hot materials is safer. The shape directs molten gold smoothly. It fits standard smelting tools. This avoids leaks. The design saves time. It minimizes waste during transfers.

How long do these crucibles last?

They last longer than regular crucibles. Silicon carbide resists wear. It handles repeated heating and cooling. Proper care extends their life. Avoid sudden temperature changes. Clean after each use. Average lifespan depends on usage intensity. Most users report months of reliable service.

Why pick graphite crucibles over other materials?

Graphite conducts heat well. It heats evenly. This speeds up melting. Silicon carbide adds strength. It beats clay or ceramic in durability. Graphite costs more initially. But it saves money over time. Fewer replacements mean lower long-term costs.

Do these crucibles work with graphite electrodes?

Yes. They pair well with high-quality graphite electrodes. The materials match thermally. This prevents uneven expansion. Electrodes fit securely. Energy transfers efficiently. The setup stabilizes the smelting process. It boosts melting consistency. Always check electrode compatibility before use.

(Polished Graphite Crucibles with Necks Cast Clay Silicon Carbide for Gold Smelting High Quality Graphite Electrodes)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Clay Graphite Crucible Graphite Vacuum Crucible With Lid High Purity Graphite Crucible

Customized Silicon Carbide SiC Ceramic Puffco Cup Ssic Insert Heating Crucible

high quality silicon carbide crucible with high streghth and purity 2KG 5KG 20KG 30 KG 60KG 80KG

100 Kgs Capacity Gas-Burned Fuel Aluminum Melting Furnace Complete With Silicon Carbide Crucible and Control Panel FCC

High Pure Isostatic Graphite Crucible Silicon Carbide Crucibles for Aluminum Metal Melting