Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

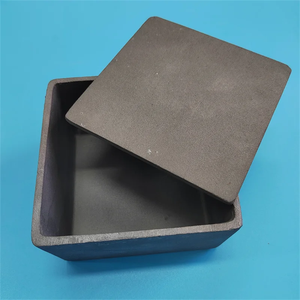

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Refractory Silicon Carbide Ceramic Sagger SiC Crucible)

Specification of Refractory Silicon Carbide Ceramic Sagger SiC Crucible

This Refractory Silicon Carbide Porcelain Sagger, additionally called an SiC Crucible, holds materials inside very warm heaters. It is made mainly from silicon carbide. Silicon carbide is unbelievably challenging. It deals with severe warm very well. This crucible endures temperature levels as much as 1500-1600 ° C conveniently. Some kinds go also greater.

It relocates heat well. This implies furnaces warm up faster. It likewise cools down quicker. This saves power. It warms up quickly without cracking. This thermal shock resistance is important. Furnace temperatures alter quickly. Various other products often break. This one endures.

The material is really hard. It stands up to damage magnificently. Crucibles see misuse. They last much longer than others. It eradicates chemical assault effectively. Many molten steels are destructive. Numerous extreme chemicals exist. The SiC crucible resists them well. This is type in steel foundries and chemical labs.

Its thickness is high. It keeps liquids secured inside. No leaks occur. This is essential for melting steels. It maintains the melt pure. Slag doesn’t permeate it quickly. This shields the liquified material.

You locate these saggers in many places. Metal foundries thaw light weight aluminum, copper, brass. They utilize them. Ceramic kilns fire ceramic and advanced ceramics. They depend on them. Chemical processing plants require difficult containers. They utilize SiC crucibles. They are vital for sintering powders. They are crucial for warmth dealing with parts. They are important for calcining minerals.

The SiC crucible provides long life span. It deals with intense heat cycles repeatedly. It conserves cash over time. Less downtime occurs. Less substitutes are needed. It performs accurately under hard problems.

(Refractory Silicon Carbide Ceramic Sagger SiC Crucible)

Applications of Refractory Silicon Carbide Ceramic Sagger SiC Crucible

Refractory silicon carbide ceramic saggers are tough containers for high heat job. These SiC crucibles handle severe temperature levels conveniently. They last a long period of time even with constant heating and cooling. This saves money gradually. Their toughness and resistance to rust are vital advantages.

Metallurgy utilizes these saggers heavily. They melt rare-earth elements like gold and silver. They additionally manage copper and light weight aluminum alloys. The crucibles do not respond with the molten steel. This maintains the metal pure. The crucibles endure the extreme heater warmth reliably.

The ceramic industry relies on them also. They terminate fine porcelain and progressed technical porcelains. Saggers protect delicate pieces inside kilns. They stop ash and gases from harming the items. Their stability makes sure regular shooting results.

Chemical handling plants need their corrosion resistance. Saggers hold harsh chemicals throughout heat responses. They resist acids and alkalis well. This makes them more secure and a lot more sturdy than various other products.

Electronic devices manufacturing utilizes SiC crucibles for crystal growth. Growing silicon or gallium arsenide crystals calls for pure problems. These crucibles supply that clean, secure atmosphere at really heats.

New materials research study additionally utilizes them. Scientists establish sophisticated compounds and nanomaterials inside SiC saggers. The crucibles take care of experimental procedures securely. Their thermal stability is essential for precise outcomes.

These crucibles function well in different furnaces. Electric kilns, gas fired heating systems, induction heaters all utilize them. They transfer heat efficiently. This conserves power. They handle sudden temperature level modifications well. This decreases breaking and damage. Their smooth surface area quits product sticking. This makes cleaning less complicated in between uses.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Silicon Carbide Ceramic Sagger SiC Crucible

What temperature can silicon carbide saggers handle?

Silicon carbide saggers withstand high heat. They work well up to 1650°C in air. Higher temperatures risk oxidation damage. Use protective atmospheres for extreme conditions above this.

How long do silicon carbide saggers last?

Their lifespan varies greatly. It depends on temperature, atmosphere, and materials processed. Compared to alumina saggers, SiC lasts much longer. Proper care means they survive many firing cycles. This reduces replacement costs.

Do SiC saggers handle thermal shock?

Yes, they handle rapid temperature changes well. Silicon carbide conducts heat superbly. This means quick, even heating and cooling. Sudden temperature shifts won’t easily crack them. This is vital for efficient kiln cycling.

What chemicals attack silicon carbide saggers?

They resist many harsh chemicals. Strong acids or alkalis can damage them over time. They won’t react with common ceramic materials like alumina or zirconia. Avoid contact with molten metals like iron or strong fluxes.

How do I maintain SiC saggers?

Keep them clean between uses. Remove any glaze drips or debris. Inspect for cracks before each firing. Handle them carefully to prevent chipping. Store them safely when not in use. Good care extends their service life.

(Refractory Silicon Carbide Ceramic Sagger SiC Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Silicon Carbide Cylinder for Bead Mill

100 Kgs Capacity Gas-Burned Fuel Aluminum Melting Furnace Complete With Silicon Carbide Crucible and Control Panel FCC

KERUI Hugh Purity Graphite Crucible High Temperature Silicon Carbide Graphite Crucible

High Temperature Resistant Graphite Silicon Carbide Crucible For Melting Metal

Crucible Corrosion Resistance and Heat Conduction Graphite Clay and Sintered Silicon Carbide Ceramic Crucible