Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

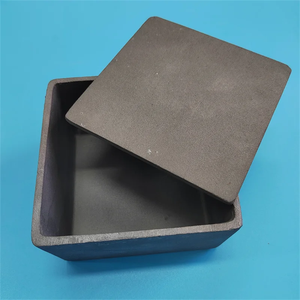

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Silicon Carbide Cylinder for Bead Mill)

Specification of Silicon Carbide Cylinder for Bead Mill

Silicon Carbide (SiC) Cylinders for grain mills are engineered to deliver outstanding performance in high-stress grinding and diffusion applications. These cyndrical tubes are crafted from premium-grade reaction-bonded or sintered silicon carbide, an innovative ceramic material renowned for its extreme hardness, put on resistance, and thermal stability. Secret specifications consist of a thickness of 3.0– 3.2 g/cm ³, making sure toughness while keeping lightweight performance. The product boasts a Vickers solidity of 24– 28 GPa, going beyond conventional products like alumina or zirconia, which decreases wear and expands life span in unpleasant settings. Thermal conductivity varieties in between 120– 150 W/m · K, allowing reliable warmth dissipation throughout long term milling procedures, important for maintaining procedure consistency and protecting against thermal destruction of delicate products. The reduced thermal growth coefficient (4.0– 4.5 x 10 ⁻⁶/ ° C )makes sure dimensional stability across temperatures as much as 1,400 ° C, decreasing the risk of fracturing under thermal cycling. Chemically inert, SiC cyndrical tubes resist corrosion from acids, antacid, and organic solvents, making them optimal for pharmaceutical, pigment, and layers markets. Regular measurements consist of inner diameters of 50– 500 mm, external sizes of 100– 600 mm, and sizes up to 1,200 mm, with tolerances as limited as ± 0.1 mm for accuracy fitment. Surface coatings can be customized to Ra ≤ 0.4 µm for minimized friction and enhanced bead movement. These cylinders are compatible with high-speed agitators, managing viscosities approximately 10,000 cP, and operate successfully in both upright and straight grain mill setups. Their high crack durability (3.5– 4.5 MPa · m ¹/ ²) guarantees resistance to mechanical shock, while the non-porous framework prevents contamination. Available in standard and customized geometries, silicon carbide cyndrical tubes decrease downtime, lower maintenance prices, and enhance grinding effectiveness by as much as 40% compared to metal options. Conformity with ISO 9001 and ASTM C1421 requirements guarantees constant high quality and reliability for important milling processes.

(Silicon Carbide Cylinder for Bead Mill)

Applications of Silicon Carbide Cylinder for Bead Mill

Silicon carbide cyndrical tubes are transforming grain mill technology throughout various industries, offering unequaled performance in grinding and distributing applications. Known for their phenomenal firmness, thermal conductivity, and deterioration resistance, these cylinders are engineered to withstand the extreme mechanical and chemical anxieties encountered in high-energy grain milling procedures.

In the chemical and layers sector, silicon carbide cyndrical tubes master handling rough slurries and thick products. Their remarkable wear resistance guarantees extended service life, even when taking care of pigments, dyes, or porcelains, lessening downtime for replacements. The material’s high thermal conductivity successfully dissipates heat generated throughout milling, avoiding overheating and preserving constant item high quality. This is essential for accomplishing consistent fragment dimension circulation in paints, inks, and layers, where appearance and security are extremely important.

The pharmaceutical and biotechnology industries take advantage of silicon carbide’s inertness and pureness, which avoid contamination during the micronization of energetic pharmaceutical components (APIs) or the manufacturing of nanoscale medication distribution systems. Their deterioration resistance makes them optimal for usage with hostile solvents or acidic/basic media, guaranteeing conformity with rigorous health and material compatibility criteria.

In electronics and advanced porcelains manufacturing, silicon carbide cylinders make it possible for exact grinding of products like silicon nitride or zirconia, important for creating parts with tight resistances. Their longevity lowers fragment shedding, essential for maintaining the purity of products used in semiconductors or high-performance porcelains.

Compared to typical materials like stainless-steel or alumina, silicon carbide supplies longer operational life, reduced maintenance prices, and greater power effectiveness due to lower rubbing and warm build-up. This translates to set you back financial savings and improved productivity. In addition, their ecological durability sustains sustainable operations by minimizing waste and power usage.

In general, silicon carbide cyndrical tubes are a game-changer for bead mills, providing accuracy, resilience, and performance throughout sectors such as chemicals, pharmaceuticals, electronics, and layers. Their adoption makes certain remarkable product quality, operational reliability, and long-term economic benefits.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Silicon Carbide Cylinder for Bead Mill

**What is a Silicon Carbide Cylinder for a Bead Mill?**

A Silicon Carbide (SiC) cylinder is a critical component in bead mills, used for grinding and dispersing particles in industries like coatings, inks, and ceramics. Made from sintered silicon carbide, it offers exceptional hardness, wear resistance, and thermal conductivity. Its primary role is to house the grinding chamber, ensuring efficient energy transfer during milling while resisting abrasion and corrosion from aggressive materials.

**Why is Silicon Carbide the preferred material for bead mill cylinders?**

Silicon Carbide outperforms metals and ceramics due to its superior properties. It has extreme hardness (9.5 Mohs), high thermal conductivity, and resistance to chemical corrosion, wear, and thermal shock. These traits ensure longevity, reduced downtime, and consistent performance in high-stress milling environments, even with abrasive slurries or high-temperature processes.

**What industries use Silicon Carbide Cylinders in bead mills?**

They are widely used in industries requiring fine grinding and dispersion, such as paints and coatings, electronics (for lithium-ion battery slurries), pharmaceuticals, ceramics, and ink production. Applications include processing pigments, nanomaterials, and advanced ceramics where precision, contamination-free milling, and durability are critical.

**How do I maintain a Silicon Carbide Cylinder?**

Regular cleaning after use prevents material buildup. Inspect for cracks or surface wear periodically. Avoid sudden thermal shocks (e.g., rapid temperature changes). Use compatible cleaning agents to avoid chemical damage. Proper alignment during installation minimizes uneven wear. Most SiC cylinders require minimal maintenance due to their inherent durability, but proactive checks ensure optimal performance.

**Are Silicon Carbide Cylinders cost-effective?**

While initially more expensive than steel or ceramic alternatives, SiC cylinders offer long-term savings. Their extended lifespan reduces replacement frequency, and their efficiency lowers energy consumption. Reduced downtime for maintenance further enhances productivity, making them a cost-effective choice for high-volume or precision-critical milling operations.

(Silicon Carbide Cylinder for Bead Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Customized high-temperature resistant silicon carbide graphite crucible for smelting gold, silver, copper, and aluminum

Silicon Carbide Graphite Crucible for Melting Aluminium 350kg Graphite Crucible

Good Quality Factory 50KG 250KG Sic Crucibles Silicon Carbide Sagger Graphite Crucible For Melting

SIC Silicon Carbide Graphite Crucible For Copper Melting

Melting Copper SiC Crucible Silicon Carbide Ceramic Crucible