Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

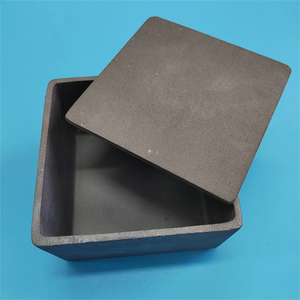

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Silicon Carbide Graphite Crucible 100kg Graphite crucible Clay Graphite crucible)

Specification of Silicon Carbide Graphite Crucible 100kg Graphite crucible Clay Graphite crucible

The Silicon Carbide Graphite Crucible (100kg capability) is a high-performance refractory vessel created for melting, holding, and casting steels and alloys in severe temperature settings. Combining silicon carbide (SiC), graphite, and clay, this crucible supplies premium thermal conductivity, thermal shock resistance, and longevity. Below are the crucial specifications:

** Product Structure: ** The crucible is made up of 50– 60% silicon carbide, 20– 30% graphite, and 10– 20% high-purity clay binder. Silicon carbide enhances hardness and abrasion resistance, while graphite improves thermal conductivity and reduces oxidation. The clay guarantees structural integrity and binds the components.

** Thermal Residences: ** Withstands temperature levels as much as 1600– 1800 ° C(2912– 3272 ° F), making it ideal for melting non-ferrous steels (light weight aluminum, copper, zinc), rare-earth elements (gold, silver), and alloys. Attributes reduced thermal growth (3.5– 4.5 × 10 ⁻⁶/ ° C )and high thermal conductivity (25– 35 W/m · K) for quick, also heating and power performance.

** Physical Specifications: ** Ability of 100kg (varies by steel density). Regular measurements consist of 400– 500mm elevation, 300– 400mm external size, and 25– 40mm wall density. Weight ranges from 50– 60kg depending upon layout. Custom dimensions are readily available.

** Chemical Resistance: ** Withstands acidic/alkaline slags, oxidation, and rust. Appropriate for hostile melting settings.

** Mechanical Strength: ** High compressive toughness (30– 40 MPa) makes certain resilience under mechanical stress and anxiety. Life-span differs with usage yet goes beyond standard clay-graphite crucibles.

** Attributes: ** Fast heating/cooling cycles, decreased splitting danger, uniform warm circulation, and compatibility with induction, electrical, or gas furnaces.

** Applications: ** Foundries, metallurgy, fashion jewelry making, recycling, and research labs.

** Handling & Upkeep: ** Preheat to 150– 200 ° C before initial usage to eliminate wetness. Avoid abrupt temperature level modifications. Tidy deposits after cooling down to prolong lifespan.

** Criteria & Certifications: ** Complies with ASTM C863, ISO 9001, and industry-specific top quality criteria.

** Product packaging: ** Shipped in wood crates with supporting to avoid transit damages.

** Service warranty: ** 6– one year, relying on supplier terms.

This crucible is an economical, durable option for high-temperature industrial applications, stabilizing performance, thermal performance, and chemical stability.

(Silicon Carbide Graphite Crucible 100kg Graphite crucible Clay Graphite crucible)

Applications of Silicon Carbide Graphite Crucible 100kg Graphite crucible Clay Graphite crucible

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Silicon Carbide Graphite Crucible 100kg Graphite crucible Clay Graphite crucible

What is the maximum operating temperature of a 100kg Silicon Carbide Graphite Crucible? The Silicon Carbide Graphite Crucible can withstand temperatures up to 1600°C (2912°F) in continuous use and briefly up to 1800°C (3272°F). Its silicon carbide (SiC) content enhances thermal shock resistance and durability, making it suitable for high-heat applications like melting non-ferrous metals, alloys, and industrial materials.

How does a Silicon Carbide Crucible compare to a standard Clay Graphite Crucible? Silicon Carbide Crucibles offer superior thermal conductivity, faster heating rates, and longer lifespan due to the added silicon carbide, which improves resistance to oxidation and chemical erosion. Traditional Clay Graphite Crucibles are more cost-effective but less durable under extreme temperatures or aggressive melting environments.

What metals can be melted in a 100kg Silicon Carbide Graphite Crucible? This crucible is ideal for melting non-ferrous metals like aluminum, copper, brass, bronze, zinc, and precious metals (gold, silver). It is not recommended for ferrous metals (iron, steel) or highly reactive metals (titanium) due to potential chemical reactions that could degrade the crucible.

How should I maintain a Silicon Carbide Graphite Crucible to extend its lifespan? Preheat the crucible gradually to avoid thermal shock, avoid overheating beyond its limit, and clean residues after each use. Store it in a dry environment to prevent moisture absorption, which can cause cracks during heating. Do not expose it to sudden temperature changes or mechanical impacts.

What is the average lifespan of a 100kg Clay Graphite Crucible with Silicon Carbide? Depending on usage conditions (temperature, metal type, handling), a well-maintained crucible lasts 30-50 melts. Harsher environments (prolonged high heat, corrosive materials) may reduce this. Regular inspection for cracks, erosion, or warping helps identify replacement needs early. Silicon Carbide variants generally outlast pure clay-graphite models by 20-30% under similar conditions.

(Silicon Carbide Graphite Crucible 100kg Graphite crucible Clay Graphite crucible)

REQUEST A QUOTE

RELATED PRODUCTS

High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

Precious Metal Smelting Graphite crucible Graphite crucibles For Melting Cast Iron

Best High-Pure Quartz Isostatic Silicon Carbide Graphite Crucible Gold Smelting Neck Cast Clay Refractory Material Melting

Corrosion Resistance To Acid Isostatic Graphite Plumbago Refractory Silicon Carbide Crucibles For Metal Melting Casting Refining

High quality sic crucible sagger high quality graphite silicon carbide ceramic crucible