Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

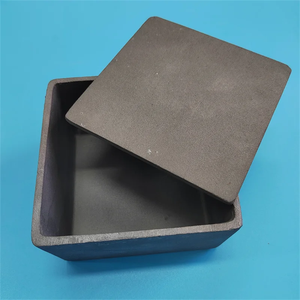

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(silicon carbide graphite crucible for aluminium meltin)

Specification of silicon carbide graphite crucible for aluminium meltin

This silicon carbide graphite crucible handles aluminum melting well. It integrates silicon carbide and graphite materials. This mix gives unique properties. The crucible resists heats properly. Aluminum thaws around 660 degrees Celsius. This crucible functions securely much hotter than that. It won’t break quickly under sudden temperature changes. Home heating and cooling down cycles take place a lot in shops. This crucible manages them dependably.

Thermal conductivity is great. Heat relocations with the crucible wall surface promptly. Your aluminum thaws faster. You save energy and time. Consistent heating happens inside the crucible. This provides you much better quality molten metal. Slag formation minimizes too. You get cleaner light weight aluminum.

Chemical resistance is solid. Molten aluminum is reactive. It attacks several materials. This crucible stands up to the assault. It does not weaken fast. Crucible life extends significantly. You change crucibles less often. This saves cash long-term. Graphite includes lubricity. This helps launch solidified light weight aluminum later on. Cleaning becomes simpler.

Mechanical stamina is high. The crucible remains tough at running temperature levels. It withstands influences throughout handling. Packing strong light weight aluminum fees is much safer. Movement on the furnace floor creates less fear. Oxidation resistance is boosted. The crucible surface area does not oxidize quickly. This protects its framework over several thaws.

Pick the appropriate size for your heating system. Capability matters for your set needs. Wall density influences warmth transfer speed. Standard forms fit most induction and fuel-fired heaters. Proper preheating prior to very first use is vital. This protects against thermal shock damages. Comply with the maker’s routine. Appropriate handling prolongs service life. Usage appropriate training tools constantly. Stay clear of bumps and declines. Store crucibles very carefully in a completely dry place.

(silicon carbide graphite crucible for aluminium meltin)

Applications of silicon carbide graphite crucible for aluminium meltin

Silicon carbide graphite crucibles handle light weight aluminum melting well. These crucibles are solid. They incorporate silicon carbide and graphite. This mix offers special qualities. Light weight aluminum shops use them daily.

These crucibles stand up to warm shock. Unexpected temperature level adjustments happen throughout melting. The crucible does not split easily. This is important. Light weight aluminum melts at high heat. The crucible holds this warmth securely. Employees remain much safer.

The material battles chemical strike. Molten light weight aluminum is extremely reactive. The crucible surface area stays solid. Less contamination occurs. Your aluminum remains cleaner. Steel quality boosts. You improve castings.

These crucibles last a long period of time. They stand up to rough use. Their stamina means less substitutes. You save money gradually. Downtime minimizes. Production stays steady.

Warm moves via them fast. Melting light weight aluminum requires good warmth transfer. These crucibles help. Your heater functions better. Power use may go down. Melting times can reduce. This aids your expenses.

The crucible form works well. Putting liquified aluminum is easier. Employees manage the flow. Less spillage occurs. Less waste takes place. Security boosts too.

Different sizes exist. You discover the ideal one for your heater. Small shops use them. Huge operations use them also. They offer many industries. Automotive components need them. Aerospace parts require them. General spreadings require them.

These crucibles offer reputable performance. They take care of tough problems. Your aluminum melting process runs smoother.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of silicon carbide graphite crucible for aluminium meltin

Here are 5 common questions about silicon carbide graphite crucibles for aluminum melting:

What makes these crucibles good for aluminum?

They mix silicon carbide and graphite. This mix is very strong. It resists the high heat needed for melting aluminum. Aluminum doesn’t stick to the surface easily. The crucible transfers heat well. This saves energy.

How hot can these crucibles get?

They handle very high temperatures. They are safe for melting aluminum. Aluminum melts around 660°C (1220°F). These crucibles work well above that point. Always check the maker’s maximum temperature rating for your specific model. Don’t exceed it.

How long do they last?

Lifespan changes a lot. It depends on the aluminum alloy used. It depends on melting temperatures. It depends on how carefully you handle the crucible. Good care makes them last longer. They resist chemical attack from molten aluminum well. They are tougher than clay-graphite crucibles.

Why do I need to preheat a new crucible?

Preheating is critical. It removes any moisture inside the crucible’s material. Moisture turns to steam quickly during heating. Steam pressure can crack the crucible. Heat them slowly to at least 300°F (150°C) before full melting heat. Follow the maker’s preheat instructions exactly.

What safety steps are important?

Never put cold metal into molten aluminum. It can cause a dangerous explosion. Always preheat scrap metal first. Never let the crucible cool down with solid aluminum stuck inside. This makes removing the metal very hard. It can damage the crucible when reheating. Use proper lifting tools. Don’t bang the crucible. Handle it gently to avoid cracks. Wear full safety gear always.

(silicon carbide graphite crucible for aluminium meltin)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity 1 To 30Kg Graphite Crucible Mold Graphite Single Ring Crucible For Casting Silicon Carbide

Customized silicon carbide crucibles s

Thermal stability high quality 1000kg silicon carbide sagger sic graphite crucible for aluminum melting

Square graphite crucible, silicon carbide sic graphite crucible

Refractory ceramic RSiC recrystallized silicon carbide sic crucible for furnace