Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

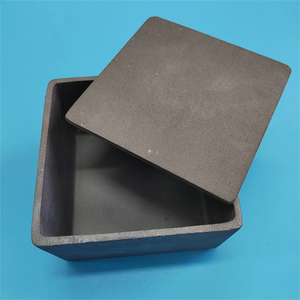

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Smelting furnace furnace 1 ton silicon carbide crucibles copper propane melting furnace)

Specification of Smelting furnace furnace 1 ton silicon carbide crucibles copper propane melting furnace

This smelting heating system thaws copper utilizing lp gas. It holds one lots of liquified metal. A silicon carbide crucible sits inside the furnace. This crucible material is really solid. It deals with high heat quite possibly. Silicon carbide resists corrosion from liquified copper. This crucible lasts longer than other types. The heater body has thick insulation. This insulation maintains heat inside the chamber. Less warm gets away. This saves propane fuel. You get more melting done per gas container. The heater gets to heats promptly. It quickly melts copper. Temperature control is accurate. Operators set the precise heat required. This avoids overheating the metal. It additionally saves power. The heater system is reliable. It mixes propane and air well. This creates a tidy, hot fire. The furnace has strong legs. These legs keep it secure during operation. Safety is necessary. The heating system style consists of standard security features. Gain access to doors open and close securely. Operators can see the melting process. Maintenance is straightforward. Replacing the crucible is simple. This heater fits tiny shops and workshops. It is trusted for melting copper sets. Develop top quality is durable. It deals with everyday use well.

(Smelting furnace furnace 1 ton silicon carbide crucibles copper propane melting furnace)

Applications of Smelting furnace furnace 1 ton silicon carbide crucibles copper propane melting furnace

This smelting heating system melts copper quickly. It makes use of propane gas for warmth. The heater holds a large 1-ton silicon carbide crucible. This crucible kind issues. Silicon carbide takes care of high warmth well. It lasts longer than various other products. Crucibles lose melting steel. A strong crucible conserves money and time. You don’t require to replace it usually.

The lp heater warms the crucible directly. This makes the melting procedure effective. You obtain copper to fluid state swiftly. Gas is easy to discover. It is a typical gas choice. This furnace matches tiny factories. It benefits workshops making copper components. It takes care of copper bars, scrap, or ingots.

Running the heating system is uncomplicated. You fill the crucible with copper. Then you spark the lp burner. The extreme flame surrounds the crucible. The copper heats up and thaws. You view the temperature. You manage the burner to keep the appropriate heat. When melted, you put the fluid copper. You put it into molds for casting. Safety gear is vital always. The furnace obtains extremely hot.

The heating system structure is developed hard. It holds up against the heats required. The layout concentrates on feature. It gets the job done melting copper accurately. The 1-ton ability is sensible. It enables decent set sizes. This heater provides a strong service for copper melting.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Smelting furnace furnace 1 ton silicon carbide crucibles copper propane melting furnace

What’s the furnace capacity?

This furnace holds one ton of molten copper. It uses a large silicon carbide crucible designed for that weight. You can melt batches up to one ton at a time. This suits small foundries or serious metalworking shops.

Why a silicon carbide crucible?

Silicon carbide crucibles are tough. They handle the extreme heat needed to melt copper. Copper melts around 1085°C (1985°F). Silicon carbide resists this heat well. It also resists chemical reactions with molten copper. This means the crucible lasts longer.

What fuel does it use?

This furnace runs on propane gas. Propane is common and easy to get. It burns very hot. This provides the intense heat required for melting copper fast. The furnace has a burner system designed for propane efficiency.

Is it safe for melting copper?

Yes, safety is built in. The furnace has strong insulation around the crucible. This keeps the outside surface cooler. It reduces burn risks. The sturdy base prevents tipping. Always wear proper protective gear. This includes heat-resistant gloves and a face shield.

How do I maintain it?

Regular checks are important. Inspect the silicon carbide crucible for cracks before each use. Cracks can cause leaks. Clean out slag and dross buildup after melting. This keeps the crucible working well. Check the propane lines and burner for blockages. Follow the manufacturer’s cleaning schedule for the furnace lining.

(Smelting furnace furnace 1 ton silicon carbide crucibles copper propane melting furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Factory Supply Industry Grade Silicon Carbide Graphite Crucible

High Pure Silicon Carbide Crucible Port Graphite Clay Metal Melting Crucible for Smelting for Metal Melting

Silicon Carbide Graphite Crucible for Melting Aluminium 350kg Graphite Crucible

Silicon Carbide Graphite Crucible for Aluminum Melting

High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding