Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

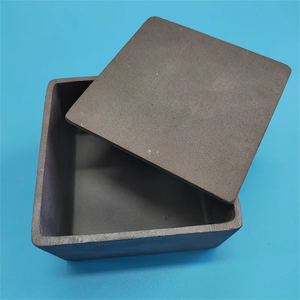

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(stationary Silicon carbide rod aluminum ingot scraps industrial smelting electric crucible melting die casting furnace)

Specification of stationary Silicon carbide rod aluminum ingot scraps industrial smelting electric crucible melting die casting furnace

This furnace melts aluminum. It handles ingots and scrap pieces. The core uses silicon carbide rods. These rods heat very efficiently. They reach high temperatures quickly. The furnace design is stationary. It stays fixed in one place. This stability helps with consistent melting. The crucible holds the molten metal. It sits inside the furnace chamber. The crucible material withstands extreme heat. Silicon carbide construction ensures durability. It resists corrosion from molten aluminum. The heating elements surround the crucible. This setup provides uniform heat distribution. Hot spots are minimized. Melting happens faster this way. Temperature control is precise. Digital controllers manage the heat levels. Operators set the desired temperature. The system maintains it accurately. This precision improves metal quality. Energy consumption is optimized. The furnace works for industrial die casting. Foundries use it daily. It processes recycled scrap efficiently. The furnace reduces waste. Operational costs are lower. Maintenance needs are reasonable. The structure is robust. It handles heavy loads easily. Safety features protect operators. Overheat protection is included. Alarms signal potential issues. The furnace suits demanding production environments. Reliability is a key benefit. Downtime is minimized.

(stationary Silicon carbide rod aluminum ingot scraps industrial smelting electric crucible melting die casting furnace)

Applications of stationary Silicon carbide rod aluminum ingot scraps industrial smelting electric crucible melting die casting furnace

Here is the product content about the silicon carbide rod melting furnace for aluminum scrap:

This furnace uses stationary silicon carbide rods for heating. It melts aluminum ingots and scraps efficiently. Industrial smelting operations find it very useful. The electric crucible design allows direct melting. Die casting shops often use this type of furnace. Silicon carbide rods are excellent heating elements. They withstand very high temperatures well. This material lasts a long time even under tough conditions. It provides consistent, reliable heat for melting metal. You put aluminum scraps directly into the crucible. The intense heat from the rods melts it quickly. It handles recycled scrap material effectively. This saves money on raw materials. The furnace works well for both small batches and larger production runs. Operators appreciate its straightforward setup. It requires minimal setup time. The controls are usually simple to understand. Maintaining the right melting temperature is easy. Silicon carbide offers great heat transfer. It gets hot rapidly and cools down safely. This minimizes wasted energy. The furnace construction is robust for factory use. It endures the demanding environment of metal foundries. Repairs are generally infrequent. Replacement parts like rods are accessible. The crucible holds the molten aluminum securely. Workers can pour the liquid metal directly into molds. This furnace streamlines the casting process. It reduces the steps needed to get molten metal. Melting happens fast with little fuss. Running costs stay reasonable. This type of furnace is a practical choice. Many businesses rely on it for daily melting tasks. It delivers good performance without complications.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of stationary Silicon carbide rod aluminum ingot scraps industrial smelting electric crucible melting die casting furnace

What is a stationary silicon carbide rod aluminum melting furnace used for? It melts aluminum scrap and ingots. People use it for die casting and industrial smelting. It heats material efficiently inside a crucible.

What materials can this furnace melt? It handles aluminum ingots well. It also melts aluminum scrap pieces. Both work fine for melting.

How hot does the furnace get? The silicon carbide heating rods get very hot. They easily reach the temperatures needed for aluminum. This means melting happens quickly.

Why is this furnace efficient? The silicon carbide rods heat up fast. They transfer heat directly to the metal. Little heat gets wasted. This saves energy.

Is the furnace safe? It has safety features. These protect the operator and the equipment. Proper installation is key. Follow the operating instructions carefully.

(stationary Silicon carbide rod aluminum ingot scraps industrial smelting electric crucible melting die casting furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Customized high-temperature resistant silicon carbide graphite crucible for smelting gold, silver, copper, and aluminum

High quality 500kg silicon carbide graphite crucibles for aluminum melting furnace

KERUI Factory Customized Silicon Carbide Graphite Crucible with Quantity

Refractory Foundry Silicon carbide sagger SiC graphite crucible

Graphite crucible With 27cm Diameter And 30 Cm Heigh Graphite-crucibl