Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

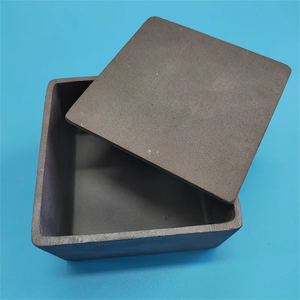

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Sintered Pure Tungsten Crucible for Melting Rare Earth Metal)

Specification of Sintered Pure Tungsten Crucible for Melting Rare Earth Metal

The sintered pure tungsten crucible is made for melting rare planet steels in high-temperature environments. The crucible is made from 99.95% pure tungsten powder processed with innovative sintering methods. This guarantees minimal pollutants, crucial for keeping the stability of responsive unusual planet steels during melting. High density (18.5 g/cm two minimum) is accomplished through exact sintering, improving structural stability and resistance to thermal shock. The product’s melting point goes beyond 3422 ° C, making it appropriate for severe heat applications. Thermal conductivity is maximized at 173 W/m · K, permitting efficient warmth transfer while protecting against unequal temperature level distribution. The crucible stands up to deterioration from acids, antacid, and molten metals, guaranteeing lengthy service life even with aggressive materials. Criterion dimensions include internal diameters from 20 mm to 200 mm and heights from 30 mm to 300 mm. Custom-made sizes are offered for particular commercial demands. Wall thickness ranges between 2 mm and 15 mm, stabilizing resilience and warm effectiveness. Surface surface is brightened to a roughness listed below Ra 0.8 µm, lessening product adhesion and streamlining post-use cleaning. The crucible’s grain structure is snugly controlled during sintering to avoid breaking under fast temperature level modifications. Applications include vacuum cleaner or inert environment heaters for melting metals like lanthanum, cerium, and neodymium. It is compatible with induction heater and electron light beam heaters. Rigorous quality assurance measures make sure each unit meets ASTM B777 criteria. X-ray evaluation verifies inner stability, while chemical evaluation verifies material pureness. The item is packaged in shock-resistant containers with moisture-absorbent materials to prevent oxidation throughout storage space. Handling standards stress making use of gloves to stay clear of contamination. Operational limits suggest preventing direct contact with carbon-based materials at heats to prevent carbide formation. Regular assessments for surface area cracks or disintegration are encouraged to keep performance. Production preparation vary from 2 to 6 weeks based upon dimension and personalization. Mass order discount rates apply for quantities above 50 systems. Technical support is readily available for assimilation with existing melting systems.

(Sintered Pure Tungsten Crucible for Melting Rare Earth Metal)

Applications of Sintered Pure Tungsten Crucible for Melting Rare Earth Metal

Sintered pure tungsten crucibles offer vital roles in high-temperature procedures entailing unusual earth steels. These crucibles take care of extreme warm successfully. Rare earth steels like neodymium, dysprosium, and terbium melt at temperatures going beyond 1,000 ° C. Ordinary products battle under such problems. Tungsten’s melting factor exceeds 3,400 ° C. This makes it ideal for extended usage without architectural failing.

The manufacturing of rare planet alloys needs purity. Tungsten crucibles stand up to chain reactions with molten steels. This stops contamination. Clean melts guarantee final products satisfy strict market standards. Electronic devices, aerospace, and renewable resource markets count on these high-purity materials. Even minor contaminations can endanger performance in magnets or superconductors.

Longevity matters in commercial settings. Sintered tungsten crucibles stand up to repeated heating and cooling down cycles. Thermal shock resistance decreases fracturing threats. This reduces replacement expenses and downtime. Graphite or ceramic choices deteriorate much faster under similar problems. Tungsten’s strength guarantees longer service life.

Energy effectiveness improves with much better warm administration. Tungsten performs warm effectively. Thawing procedures call for less energy to keep target temperature levels. This reduces functional costs. Ecological guidelines press markets towards lasting methods. Efficient crucibles support these objectives.

Precision production benefits from tungsten’s stability. Crucibles keep form under tension. Constant measurements make sure uniform heating and melting. This is crucial for applications like semiconductor doping or laser crystal growth. Repeatable outcomes issue in study and automation.

Handling responsive metals poses challenges. Tungsten’s inert nature avoids undesirable responses. Security improves during melting of unstable aspects. Workers prevent exposure to dangerous fumes from material destruction.

Custom creates adjust to specific requirements. Crucibles come in varying dimensions and densities. This adaptability suits research laboratory experiments and large commercial furnaces. Compatibility with vacuum cleaner or inert gas settings broadens their usage instances.

High initial prices offset long-term financial savings. Decreased maintenance and substitutes make tungsten crucibles cost-efficient. Industries prioritize dependability in important processes. Performance consistency validates investment.

Uncommon earth steel demand expands with progressing technology. Sintered tungsten crucibles stay necessary for quality and effectiveness. Their role sustains development throughout multiple modern industries.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Sintered Pure Tungsten Crucible for Melting Rare Earth Metal

A sintered pure tungsten crucible melts rare earth metals. People often ask these questions. What makes a sintered pure tungsten crucible different from regular crucibles? It is made by pressing tungsten powder at high heat. This creates a dense structure. The structure handles extreme temperatures better. Regular crucibles use cheaper materials. These materials fail under high heat or reactive metals.

Why choose tungsten for melting rare earth metals? Tungsten has the highest melting point of all metals. Rare earth metals need temperatures above 1500°C. Tungsten stays solid. It resists corrosion from reactive melts. Materials like graphite or ceramics break down. Tungsten lasts longer.

How hot can the crucible get before failing? Sintered tungsten crucibles work up to 2000°C. They stay stable in air or vacuum. Prolonged use near the limit may cause slow wear. Avoid sudden temperature changes. This prevents cracks.

What rare earth metals work with this crucible? It melts lanthanum, cerium, neodymium, and similar metals. These metals react with oxygen. The crucible’s purity stops contamination. It works in furnaces with argon or vacuum. This keeps melts clean.

How long does the crucible last? Lifespan depends on usage. High temperatures or frequent thermal cycling shorten it. Proper care helps. Clean residue after each use. Store it dry. Check for cracks or warping. Replace it if defects appear. A well-made crucible lasts months in regular conditions.

(Sintered Pure Tungsten Crucible for Melting Rare Earth Metal)

REQUEST A QUOTE

RELATED PRODUCTS

KERUI Corrosion Resistance To Acid Sic Graphite Crucible Silicon Carbide Graphite Crucible

CNMI Graphite Crucible Double Ring 2Kg Custom STA High Temperature Silicon Carbide Electronic Crucible

30kg 50kg 60kg 100kg Large Silicon Carbide Graphite Carbon Crucible for Melting Cast Iron Metal

Silicon Carbide Graphite Crucible for Induction Furnaces

Graphite crucible With 27cm Diameter And 30 Cm Heigh Graphite-crucibl