Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

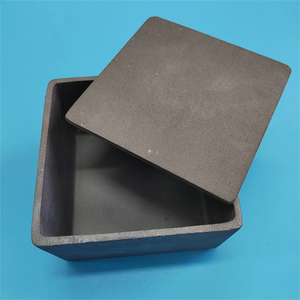

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting)

Specification of Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting

This product is a personalized silicon carbide clay graphite crucible designed for melting applications. It handles weights from 100kg to 1800kg. The crucible integrates silicon carbide and high-purity graphite. This mix makes sure high thermal conductivity and resistance to severe temperatures. It works well in atmospheres approximately 1600 ° C. The material structure stops splits and extends life span under rapid heating or air conditioning.

The crucible is built for resilience. It stands up to chemical erosion from molten steels, slag, and changes. This minimizes wear during repeated usage. The layout consists of enhanced edges and a thick base. These features enhance security and stop contortion under heavy loads. Custom-made sizes and shapes are readily available. Choices consist of round, oval, or rectangular kinds. Wall density and elevation can be adjusted to fit details heating system arrangements.

This crucible fits industrial melting procedures. It deals with steels like iron, light weight aluminum, copper, and precious metals. It pairs with induction heaters, electrical arc heating systems, or gas-fired systems. The high thermal efficiency quicken melting cycles. This reduces power costs. The reduced porosity of the material lessens steel absorption. This keeps thaw purity high and minimizes waste.

Production utilizes advanced sintering strategies. These approaches make certain even thickness and stamina across the crucible. Each device undergoes strict quality checks. Tests include thermal shock resistance, lots ability, and leakage evaluations. This ensures dependability in harsh conditions.

Personalized orders need details like wanted ability, operating temperature, and steel kind. The production group adjusts material proportions and layout parameters as necessary. Preparations vary based on complexity. Common options ship faster. Technical assistance is available for installment and maintenance.

The crucible’s surface is smooth. This makes cleansing much easier and lowers residue buildup. Handling is safer as a result of the non-stick homes. Safety standards satisfy commercial demands for high-heat equipment. Replacement components and repair services are provided for long-term use. Pricing depends on size, personalization, and order volume. Bulk acquisitions obtain discounts. Examples can be checked before full orders.

(Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting)

Applications of Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting

Personalized silicon carbide clay graphite crucibles deal with weights from 100kg to 1800kg. These crucibles are developed for melting metals like iron, copper, light weight aluminum, and alloys. The product incorporates silicon carbide, clay, and graphite. This mix provides high thermal conductivity. It likewise stands up to severe warm and thermal shock. Industries utilize these crucibles in foundries, metal casting, and recycling. They work well in high-temperature furnaces. The layout stops splits and expands service life.

The crucibles come in customized dimensions. Users choose based upon heater kind and melting needs. Smaller units (100kg-500kg) in shape small operations. Bigger designs (1000kg-1800kg) fit heavy commercial use. Modifications in wall density boost warmth distribution. Personalized forms lower metal waste. The surface therapy prevents slag buildup. This keeps the molten metal pure.

These crucibles last longer than typical options. They deal with duplicated heating cycles without breaking down. This reduces replacement expenses. The product resists chemical reactions with molten metals. It prevents contamination. Employees handle them securely. The crucibles remain steady during fast temperature level changes. This reduces mishaps.

Manufacturing facilities save power with these crucibles. The high thermal conductivity speeds up melting. Much less gas is needed. Production cycles shorten. Costs go down. Upkeep is basic. No unique devices are required. The crucibles operate in electrical, gas, or oil-fired heating systems. They perform in vacuum or managed environments.

Customers give heating system specifications and steel types. Manufacturers customize each crucible. This ensures excellent fit and function. Testing checks warmth resistance and toughness. Distribution times differ with dimension and style. Worldwide distributors offer these products. Rates depend on products and customization.

The crucibles are shipped with safety product packaging. Taking care of standards avoid damage. Customers keep them in dry locations. Correct preheating before very first use is encouraged. This stays clear of thermal anxiety. Regular assessments place very early wear. Extra components are readily available. Technical assistance helps with setup.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting

What is a silicon carbide clay graphite crucible used for?

This crucible melts metals like iron, copper, aluminum at high temperatures. It combines silicon carbide, clay, graphite. These materials make it strong, heat-resistant, durable. It transfers heat well, handles sudden temperature changes. Factories and foundries use it for casting, alloy production, recycling scrap metal.

Can the crucible size be customized?

Yes. Sizes range from 100kg to 1800kg. Custom shapes, thicknesses, designs are possible. Adjustments depend on furnace type, metal melted, production needs. Share your requirements. We tailor dimensions, wall thickness, base style. This ensures compatibility with your equipment and process.

What temperature can it withstand?

It resists temperatures up to 1600°C to 1800°C. Exact limits depend on material ratios, crucible design. Check specifications before use. Exceeding recommended temperatures cracks or warps the crucible. Monitor heat levels during melting. Avoid rapid heating or cooling.

How long does the crucible last?

Lifespan varies with usage frequency, metal type, operating conditions. Proper care extends it. Avoid overheating, physical impacts, chemical reactions. Follow cooling procedures. Clean after each use. Typical lifespan ranges from months to years. Replace if cracks, erosion, or deformation appear.

How to maintain the crucible?

Inspect for cracks before heating. Remove slag or residue after melting. Store in a dry area. Use gentle tools for cleaning. Repair minor cracks with heat-resistant cement. Never expose a damaged crucible to high heat. Follow manufacturer guidelines for handling, storage, maintenance.

(Customized Silicon Carbide Clay Graphite Silicon Carbide Crucible 100kg to 1800kg for Melting)

REQUEST A QUOTE

RELATED PRODUCTS

High quality sic crucible sagger high quality graphite silicon carbide ceramic crucible

High Wear Resistance Silicon Carbide Crucible Factory Multi-Size Custom Service Ceramic Parts Refractory Welding

Melting furnace with silicon carbide clay with inclined melting furnace graphite crucible

Custom Clay Graphite Crucible Graphite Vacuum Crucible With Lid High Purity Graphite Crucible

factory delivery furnace boat ceramic sic sagger large tunnel kiln silicon carbide crucible