Premium Ceramic Crucibles | High-Performance Lab & Industrial Solutions

PRODUCT PARAMETERS

Description

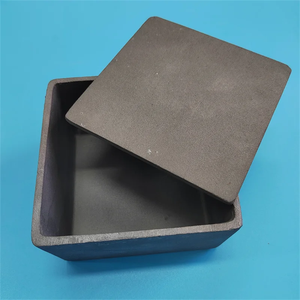

Overview of Silicon Carbide Crucible

Silicon carbide (SiC) crucibles are advanced ceramic vessels known for their exceptional thermal conductivity, high strength, and resistance to thermal shock. These crucibles can withstand extreme temperatures up to 1600°C and are highly resistant to chemical attack, making them ideal for melting metals, alloys, and other materials in both laboratory and industrial settings.

Features of Silicon Carbide Crucible

High Thermal Conductivity: Efficient heat transfer ensures uniform heating and rapid temperature changes.

Thermal Shock Resistance: Can endure rapid temperature fluctuations without damage.

Chemical Inertness: Resistant to most acids and alkalis, minimizing contamination.

Temperature Range: Operates effectively at temperatures up to 1600°C.

Mechanical Strength: Extremely durable and strong, even under harsh conditions.

Non-Reactive: Does not react with the materials being processed, preserving sample purity.

Long Service Life: Durable construction ensures extended use and reliability.

(MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for )

Specification of MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for

The MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible is designed for high-temperature commercial applications. This item integrates silicon carbide and graphite products. The mix makes certain remarkable warm resistance and toughness. The crucible deals with severe temperature levels as much as 1800 ° C. It functions well in atmospheres requiring quick heating or cooling. Thermal shock resistance stops fractures under unexpected temperature changes. The material stands up to chemical corrosion from acids, antacid, and molten steels. This prolongs the crucible’s life span.

The crucible’s framework is dense and non-porous. This lowers contamination during steel melting or alloy manufacturing. It is ideal for heating gold, silver, copper, and rare metals. The style matches ceramic sintering, glass handling, and laboratory experiments. Uniform warm circulation enhances process efficiency. Users conserve energy and decrease functional costs.

The product outshines conventional clay or alumina crucibles. It lasts longer under repeated thermal tension. Maintenance requirements are very little. The smooth surface protects against material bond. Cleansing is easy after each use. Several sizes and shapes are available. Personalized designs match particular heater setups or production needs.

MUZI CARBON Manufacturing facility uses sophisticated molding and sintering strategies. Each crucible undertakes rigorous top quality checks. Accuracy production makes certain regular wall density and architectural integrity. The item meets global criteria for industrial refractory materials. It is extensively utilized in factories, metallurgy laboratories, and precious jewelry workshops.

The crucible deals with electric, gas, and induction furnaces. Compatibility with various home heating techniques includes flexibility. High thermal conductivity speeds up melting procedures. Operators accomplish faster manufacturing cycles. Bulk orders consist of tailored product packaging to prevent damage throughout shipping. Technical assistance assists customers select the ideal design. A 1 year service warranty covers product issues.

The style concentrates on individual safety and security and operational reliability. Steady efficiency minimizes downtime in industrial settings. Cost-effectiveness makes it a sensible selection for tiny workshops and large manufacturing facilities. Checking data confirms constant results throughout batches.

(MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for )

Applications of MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for

MUZI CARBON Factory makes refractory silicon carbide saggers and SIC graphite crucibles for high-temperature industrial uses. These items handle severe warm and extreme problems. They function well in steel melting, ceramic shooting, chemical handling, and other demanding settings. The silicon carbide saggers are built to last. They stand up to thermal shock, corrosion, and put on. This makes them optimal for duplicated home heating and cooling down cycles. Factories use them in kilns to hold ceramic components throughout shooting. They keep products steady and stop contamination. The saggers also work in heat treatment procedures. They keep toughness also at temperatures over 1600 ° C.

The SIC graphite crucibles are created for melting steels. They take care of light weight aluminum, copper, gold, and alloys. The material incorporates silicon carbide with graphite for far better thermal conductivity. This quickens melting and conserves energy. The crucibles do not fracture under rapid temperature level changes. They last longer than traditional clay or ceramic choices. Foundries and fashion jewelry manufacturers rely upon them for consistent performance.

Chemical plants utilize these products as well. The silicon carbide material stands up to acids and alkalis. It stays steady in responsive environments. This makes the saggers suitable for chemical reactors or driver supports. Semiconductor producers use them in crystal development processes. The high pureness of the product stops contamination of delicate products.

Both products are very easy to handle. Their lightweight design reduces employee stress. They call for minimal maintenance. Customers conserve cash over time due to their sturdiness. MUZI CARBON Factory customizes shapes and sizes to fit certain machinery. This guarantees compatibility with different furnaces or production lines.

These remedies fulfill strict market requirements. They enhance effectiveness in high-temperature applications. Companies throughout steels, porcelains, chemicals, and electronic devices take advantage of their reliability. The items lower downtime and reduced replacement costs.

Company Introduction

Welcome to Teen-Hot,a leading global supplier of high-quality crucibles designed for various industrial applications. We offer an extensive range of crucibles, including graphite, ceramic, and metal varieties, tailored to meet the needs of foundries, laboratories, and manufacturers. Our products are renowned for their durability, thermal resistance, and precision engineering, ensuring optimal performance in melting and heat treatment processes. With advanced manufacturing facilities and a commitment to excellence, we provide reliable, cost-effective solutions worldwide. Partner with us for your crucible needs and experience superior quality, expert support, and timely delivery.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for

The MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible handles high-temperature industrial processes. Here are 5 FAQs. What is a silicon carbide sagger crucible? It is a container made from silicon carbide and graphite. It resists extreme heat and chemical corrosion. It is used for melting metals or holding materials during heating. How hot can it withstand? The crucible works in temperatures up to 1650°C. It stays stable under rapid heating cycles. This makes it suitable for furnaces and foundries. What benefits does it offer over other materials? It lasts longer than clay or ceramic crucibles. It resists thermal shock better. It reduces cracking or breaking during temperature changes. This lowers replacement costs over time. Where is it commonly used? It serves in metal casting, glass manufacturing, and laboratory experiments. It melts gold, silver, aluminum, and alloys. Industries needing precise high-heat processing prefer it. How do you maintain it? Clean it after each use to remove residue. Avoid sudden cooling after heating. Store it in a dry place to prevent moisture damage. Check for surface cracks regularly. Proper care extends its lifespan.

(MUZI CARBON Factory refractory silicon carbide sagger SIC graphite crucible for )

REQUEST A QUOTE

RELATED PRODUCTS

Clay graphite crucible/silicon carbide crucible with pincers, tongs

China Polished Surface Smelting Pure Tungsten Crucible for

Sintered Pure Tungsten Crucible for Melting Rare Earth Metal

High Quality Best Induction Melting Molybdenum crucible

High quality low ceramic industry SiC silicon carbide sagger/crucible